Medical device solutions

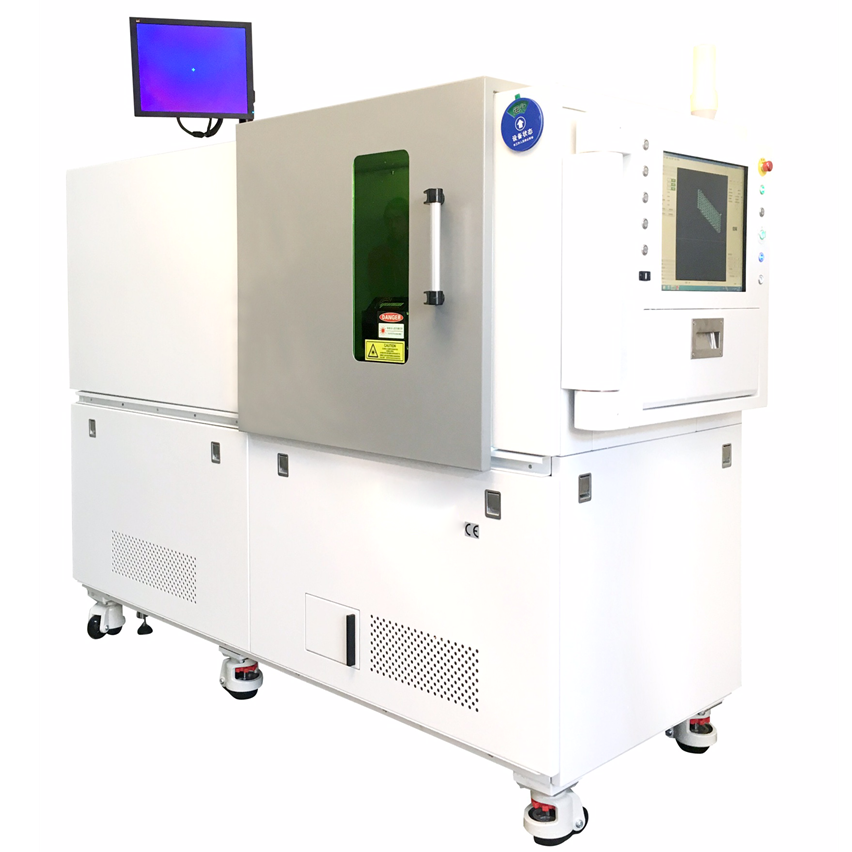

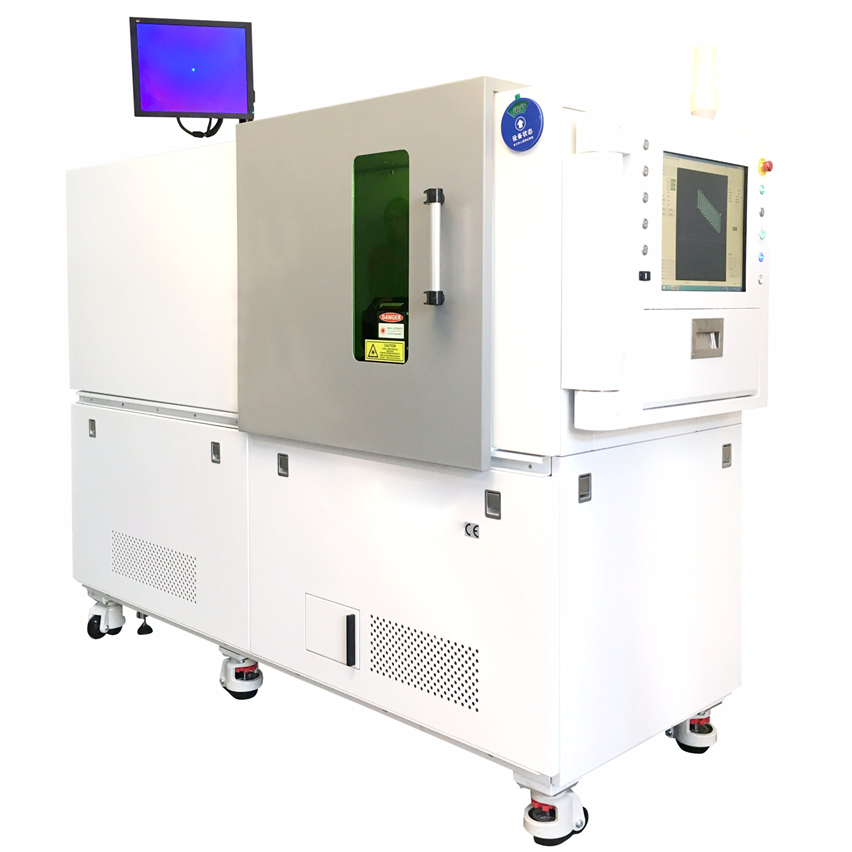

Laser Cutting Machine for Medical Stent YC-SLC300

Medical stent laser cutting machine

SLC300 medical stent laser cutting machine is a kind of medical precision laser cutting machine, mainly used for laser micromachining of various bare metal stents and drug-coated stents, such as coronary stents, coronary bare metal stents, drug-coated coronary stents Stent, venous filter microstructure stent, compared with YC-BSLC300 laser cutting machine, this equipment has lower laser power configuration, thinner material wall thickness, and the cut stent is relatively small, so it belongs to the small metal stent laser cutting machine. BSLC300 laser cutting machine is mainly used for laser micromachining of large metal stents such as valve stents, mitral valve stents, and peripheral stents.

YC-SLC300

Technical Parameters:

| Maximum operating speed | 300mm/s(X) ;100mm/s(Y)for option ;100mm/s(Z);600rpm(θ) |

| Positioning accuracy | ±1um(X);±3um(Y)for option;±3um(Z);±15arcsec(θ); |

| Repetitive positioning accuracy | ±0.2um(X);±1um(Y)for option;±1um(Z);±3arcsec(θ) |

| Cutting seam width | 15um~25um |

| Consistency of reinforcement width | <±5um; |

| Machining material | 316L & Ni-Ti & L605 & Fe & Mg & Zn and other alloy materials |

| Tube blank length | <2.5m (customized support fixture) |

| Processing wall thickness | 0~0.3±0.02mm; |

| Processing pipe diameter | Φ0.1~Φ7.5±0.02mm; |

| Single processing range | 0~300mm (longer products will be machined by segmented splicingmethod); |

| Laser type | Fiber laser; |

| Laser wavelength | 1030-1070±10nm; |

| laser power | 100W&200W&300W for option; |

| Equipment power supply | 220V± 10%, 50Hz;AC 20A (main circuit breaker); |

| File format | DXF、DWG; |

| Equipment dimensions | 2000mmx1000mmx1600mm; |

| Equipment weight | 1500Kg; |

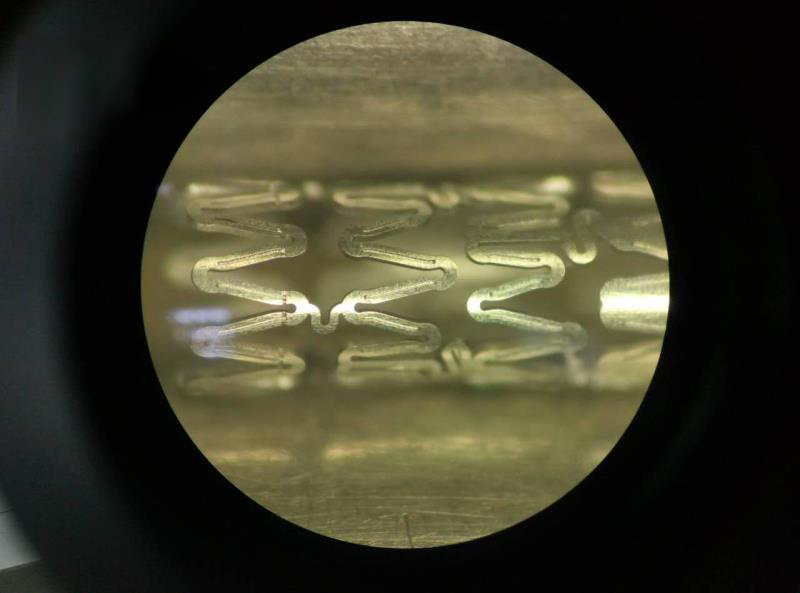

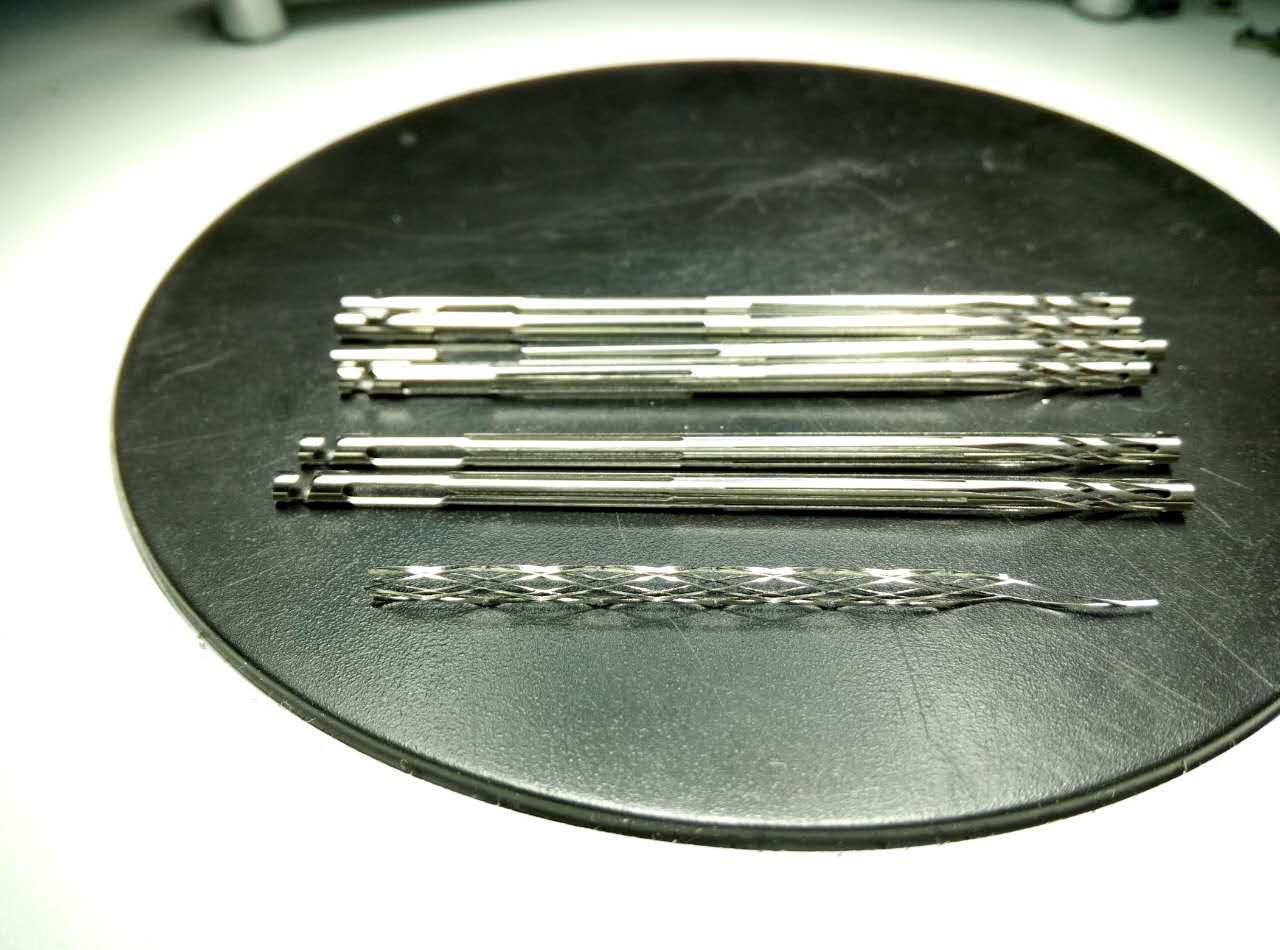

Sample Exhibition:

316L & L605 bare

metal coronary stent

Ni-Ti- Φ 2.7mm-

WT0.2mm coronary stent

L605- Φ1.8mm-WT0.15mm

drug coated coronary stent

microstructure

Ni-Ti- Φ 2mm-L100mm

-WT0.2mm coronary stent

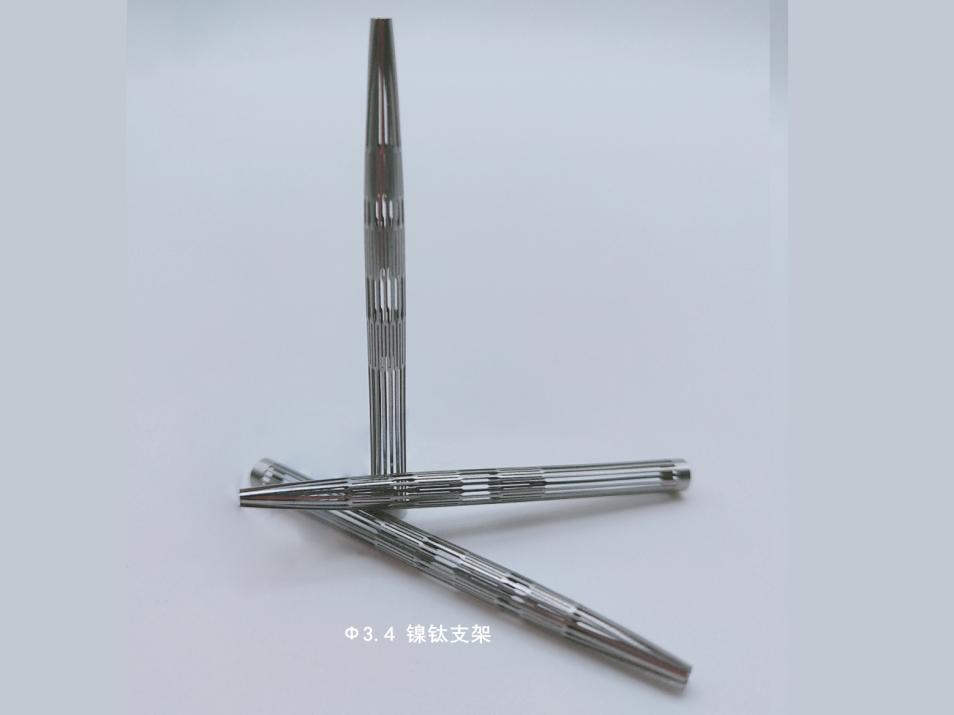

Ni-Ti- Φ 3.4mm-WT0.2mm

coronary stent

Φ2.03mm-WT0.2mm

venous filter microstructure

Application scope

օ Laser micromachining of bare metal stent and drug coated stent such as coronary artery stent and vein filter

High precision machining

օ Small cutting seam width: < 20um

օ High machining accuracy: ≤ ± 5um

օ Good quality of incision: no burr & smooth incision

օ High machining efficiency: one-off cutting through one side pipe wall & continuous automatic feed machinin

Strong adaptability

օ Have the ability of laser dry cutting & wet cutting & drilling & blind slotting and other fine machining technology

օ Support the centripetal, vertical and compound opening feature machining of equal diameter tube, variable diameter tube and plane instrument

օ Can machine 316L & Ni-Ti & L605 & Fe & Mg & Zn and other alloy materials

օ Compatible with precision D-type chuck & ER series chuck & three-jaw chuck and other precision thin-walled tube clamping system

օ Adopt the combined precision thin-walled tube shaft sleeve support system with self-adaptive shape tolerance variation

օ Provide the matching scheme of precision thin-walled tube continuous automatic feeding machining & dry / wet cutting and sealing material receiving

օ Equipped with self-developed 2D & 2.5D & 3D CAM software system for laser micromachinin

Flexible design

օ Follow the design concept of ergonomics, delicate and concise

օ Equipped with machine vision system to real time online monitor the laser dynamic machining process

օ The software and hardware functions match flexibly, support personalized function configuration & intelligent production management

օ Support forward innovative design from component level to system level

օ Open type control & laser micromachining software system is easy to operate & intuitive interface

Technical certification

օ CE

օ ISO9001

օ ISO13485

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur