Precision 3c solution

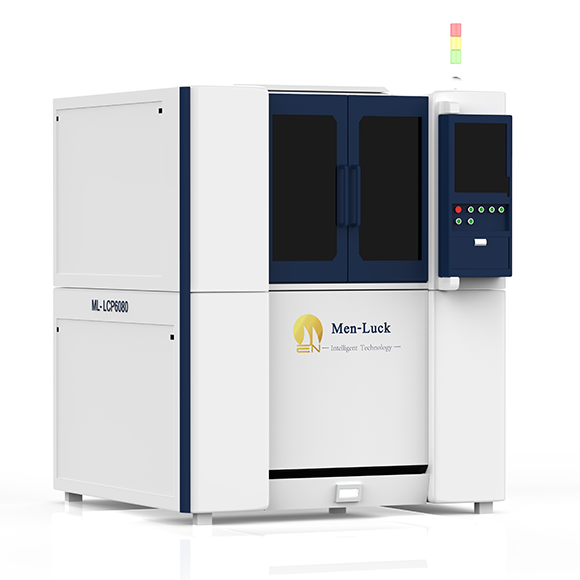

ML-LCP6080 Precision plane fiber laser cutting machine

Introduction of precision plane fiber laser cutting machine:

Precision plane fiber laser cutting machine can be used for copper and aluminum substrate, ceramic substrate, PCB board, gold and silver jewelry, LED lighting and other kinds of ceramic materials, high inverse materials, magnetic materials, stainless steel alloy materials precision laser cutting, drilling, the equipment is men-luck combined with many years of production experience and market demand design of a precision laser micro-processing equipment. Widely used in electronic 3C, precision hardware, auto parts and other industries.

Precision plane fiber laser cutting machine main components:

Precision plane laser cutting machine is mainly composed of fiber laser, optical system, cutting head, motion system, control system, cooling system and other accessories, each part is indispensable.

Laser is the core component of laser cutting machine, determines the precision, quality and speed of cutting, it is these advantages of laser, can meet the cutting needs of a variety of materials and a variety of shapes. We use custom laser, electro-optical conversion efficiency is high, low energy consumption, energy saving and environmental protection.

The optical system is also an important part of the laser cutting machine, mainly by focusing lens, mirror, beam splitter, etc., laser beam through the mirror and beam splitter, and then through the focusing lens focus, the laser energy gathered to a very small area, and then achieve high precision and high efficiency cutting process;

Cutting head as the cutting machine executive parts are mainly composed of nozzles and cutting liquor, nozzle spray protective gas, to avoid cutting the material is oxidized, cutting nozzle will focus the laser beam to the surface of the material, forming a high temperature and high pressure area, the material to achieve cutting requirements;

The motion system mainly includes X axis, Y axis, Z axis, etc., through the reciprocating movement of these axes, the cutting head can move along the preset path to achieve various cutting effects;

The control system is the control center of the laser cutting machine, mainly including the computer, control card, sensors, etc., the computer is mainly responsible for controlling the entire cutting process, the control card mainly converts the control signal into an electrical signal, so that the drive motor moves, the sensor is mainly used to monitor the displacement and speed of the material and then feedback to the computer for closed-loop control. The operation screen of men-luck laser cutting machine adopts rotating shaft design, which is easy to operate, and the system adopts powerful software function, which can automatically optimize the cutting path and improve the cutting effect.

The cooling system is an auxiliary system for cooling. Laser cutting machine working process will produce a lot of heat, in order to avoid high temperature, affecting the normal operation of the equipment, so generally configured cooling system.

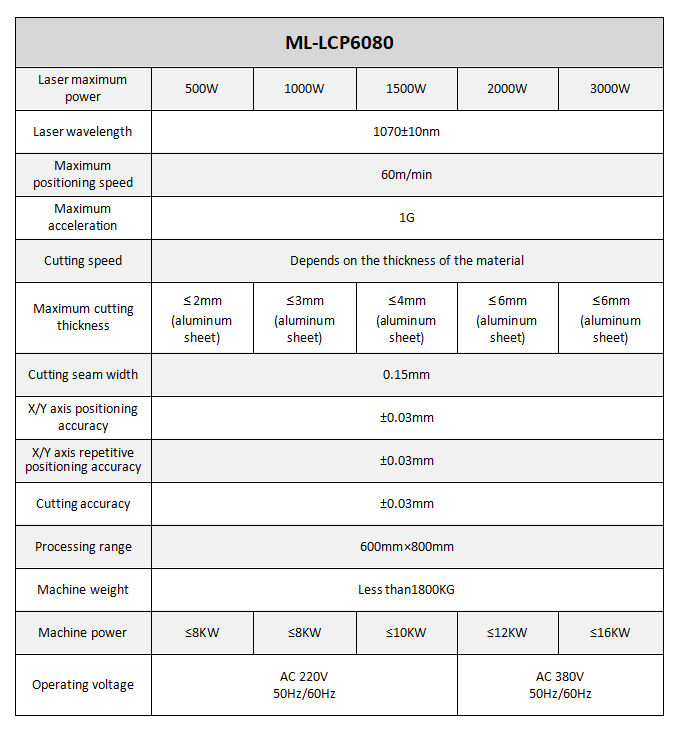

Precision plane fiber laser cutting machine specifications:

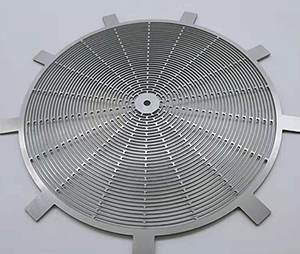

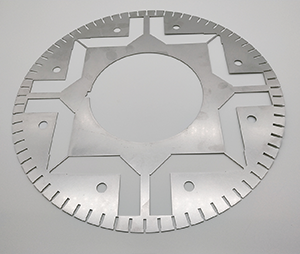

Precision plane fiber laser cutting machine sample display

After years of market and production precipitation, men-luck has continuously upgraded the laser micromachining equipment. At present, the main products are fiber laser cutting machine, femtosecond laser cutting machine, glass laser cutting machine, ceramic laser cutting machine, PCB laser cutting machine, etc., which can be used for cutting various materials of stainless steel plate such as ceramics and metals. men-luck has maintained long-term cooperation with famous laser optical manufacturers in the United States and Europe, and has maintained friendly and close communication with new and old customers in laser cutting, drilling, engraving, marking, welding and other fields. After years of unremitting learning and efforts, men-luck has upgraded and improved the equipment process, making the precision of laser optical micromachining equipment more and more high. The quality is getting better and better, the efficiency is also getting higher and higher, and we are always at the forefront of the industry. At present, our laser equipment performance is stable, cost-effective, adhere to provide customers with the highest cost-effective laser processing equipment.

We always adhere to the customer as the center, firmly believe that quality first, integrity management, with the most advanced laser processing equipment and high-quality after-sales service to repay our customers and friends, to provide the market with high quality, environmental protection, cost-effective laser application solutions, hope that friends in the world to become partners.

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur