Femtosecond lasers are also ideal for manufacturing refined medical fluid delivery devices such as loops, catheters, and needles. The device is mostly made of metal, and the femtosecond pulse prevents the surface from melting and the resulting structural changes. If it is made of polymer, potential toxicity and structural damage can also be avoided.

Plastic medical tubes are more stringent and often require slots or holes to be created to deliver medicine. If a specific gas or drug flow is to be created through these tubes, they must be of a highly controllable, repeatable size. After drilling a small hole and applying a specific pressure, the flow height from one tube to another will be controlled.

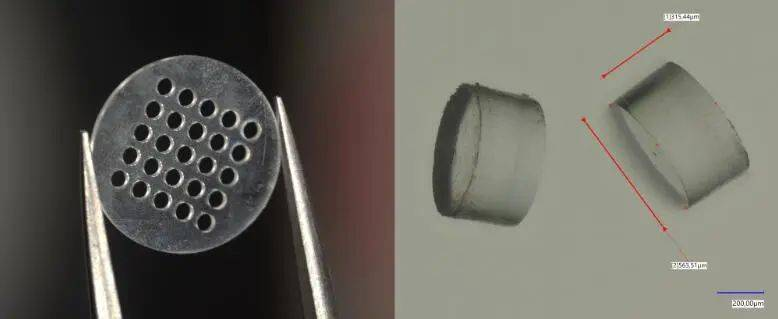

Drilling small holes in microfluidic medical devices is one of the best applications for femtosecond lasers.

(Photo credit: Fluence Technology)

In addition, with the increasing number of applications where metal parts and equipment need to be connected, laser welding has also become a necessary process for many medical device manufacturers. With the ability to precisely connect individual components to create a structural bond, or to form a sealed structure to avoid leakage or penetration, the highly precise welding capabilities of the femtosecond laser can be used for welding between very fine components.

Due to traceability and quality inspection standards, the identification code marking of device parts in the manufacturing process of many medical devices may soon become mandatory. For marking applications, only sophisticated processes such as laser equipment can process the marking of such products without affecting the function of the equipment or components. In particular, the femtosecond laser, at the same time as the laser marking, will not change the composition and surface shape of the product material, to ensure that the marking part will not be corroded during the sterilization process.

For those in the medical device manufacturing industry, a major challenge in purchasing a new generation of micro laser equipment is to choose between femtosecond lasers and fiber lasers. Fiber lasers also have a major advantage: high power, enabling faster cutting and thicker parts. However, for thinner parts, the power and speed advantages are often greatly reduced due to the need to reduce the repetition rate and avoid cumulative thermal damage, so femtosecond laser micromachining equipment is generally selected. In fact, the specific choice of equipment depends on the processing material and quality requirements and the specific application scenario.

Changzhou Men-luck Intelligent Technology Co., Ltd. long-term supply of all kinds of laser cutting equipment, laser welding equipment and laser marking equipment, and can according to the specific needs of customers, provide professional equipment customized processing solutions, with the highest efficiency and best quality to complete the required equipment processing, in addition, our company can also provide proofing services, Please feel free to call +86 180 9444 0411 for more information.

Post time: Jul-28-2023