In recent years, laser processing has been increasingly used in medical device manufacturing, such as precision laser cutting equipment, medical laser welding equipment, laser drilling equipment, laser marking equipment, etc. These equipment can be used to process medical stents, heart valve stents, endoscopic Bending Sections and all kinds of surgical instruments.

Fiber lasers occupy a dominant position in the medical device manufacturing industry due to their low cost, scalable power and other advantages. Laser devices such as picosecond and femtosecond have great advantages in terms of cutting quality, but their market share has been relatively small for a long time.

In recent years, with the increasing requirements of precision medical devices for cutting quality, the core device research and development of laser medical equipment is accelerated, and ultrafast lasers such as femtoseconds will become the preferred laser in medical equipment manufacturing application scenarios, and these lasers are constantly penetrating various fields of medical treatment.

Of the medical devices manufactured using femtosecond lasers, neurological and cardiovascular stents are the most common. The femtosecond laser enables precise machining of burrless, micron-scale stent products on medical device products, which is critical to prevent immune reactions/rejection when inserted into the human body. Many medical stents are made of nickel-titanium alloy, the past use of mechanical technology to process this nickel-titanium alloy is not easy, femtosecond laser has become an effective means.

The concept of “intervention without implantation” is an important trend in the innovative development of coronary interventional therapy. Heart stents so far can be divided into four stages: pure balloon dilation, bare metal stents, drug-eluting stents, and biodegradable stents.

Unlike previous heart stents, biodegradable stents are scaffolds made of degradable polymer materials (such as polylactic acid) that can be decomposed and absorbed by the human body within a certain period of time. When the blood vessels are remodeled, the stent degrades directly into water and carbon dioxide in the body, compared to traditional metal – and drug-coated stents. Existing research evidence shows that the efficacy of biodegradable stents is certain, which can eliminate the influence of residual bare stents on the recovery of vascular function and reduce the incidence of long-term adverse events after PCI.

With its unique advantages, degradable stent materials will gradually become the mainstream trend in the development of international heart stent technology. In the processing of this polymer material and other non-metallic materials, if the fiber laser processing, the material may be heated and change the chemical composition, which may produce biological toxicity. If you want to reduce these thermal effects and ensure the quality of the processing effect, the first choice is femtosecond laser equipment.

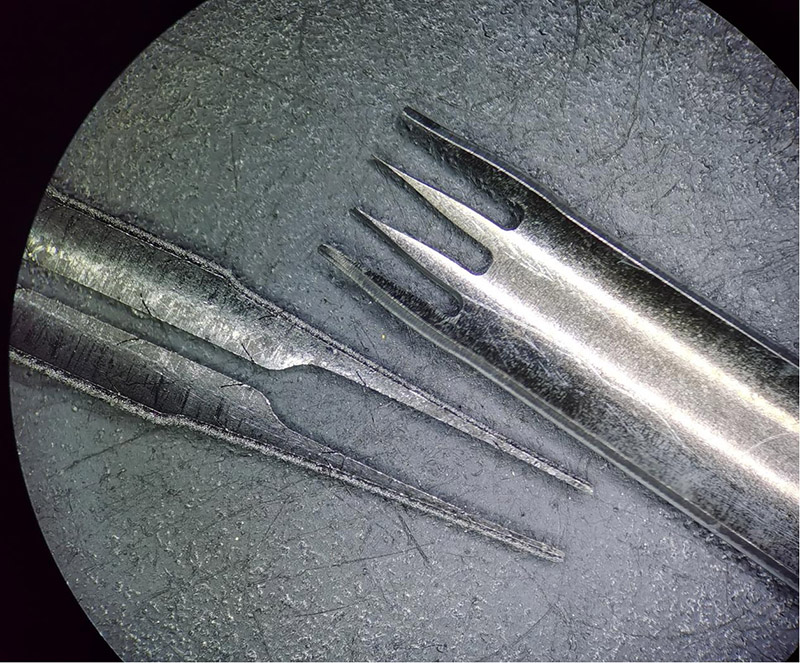

One of the main advantages of using femtosecond (10^-15s) pulses compared to nanosecond or even picosecond pulses is that the contact time between the beam and the workpiece is reduced as much as possible, minimizing the heat affected zone on the workpiece and thus reducing the adverse effects caused by excessive heating. For some medical devices, including stents, this is also critical to improving the biocompatibility of implant materials.

Femtosecond lasers can process products with high precision. Medical coronary stents usually range in diameter from 2 to 5mm and in length from 13 to 33mm. A femtosecond laser device is recommended if you want high-quality stent details and cuts that reduce the risk of biopolymer changes or metal oxidation. From the perspective of the entire stent manufacturing process, another advantage of the femtosecond laser is to minimize the post-processing needs after cutting the stent.

Femtosecond laser cutting vs Fiber laser cutting effect

Recent advances in femtosecond laser technology have injected greater capabilities into precision medical device processing, eliminating thermal effects while minimizing post-processing.

Post time: Jul-25-2023