Precision 3c solution

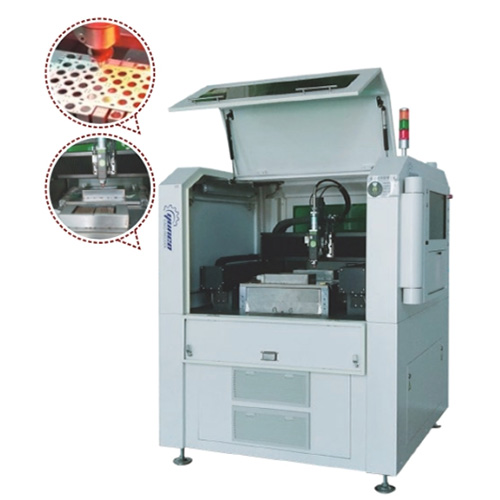

ECLC6045 Precision Laser Cutting Machine for Hard Brittle Materials

Precision laser cutting machine for hard and brittle materials

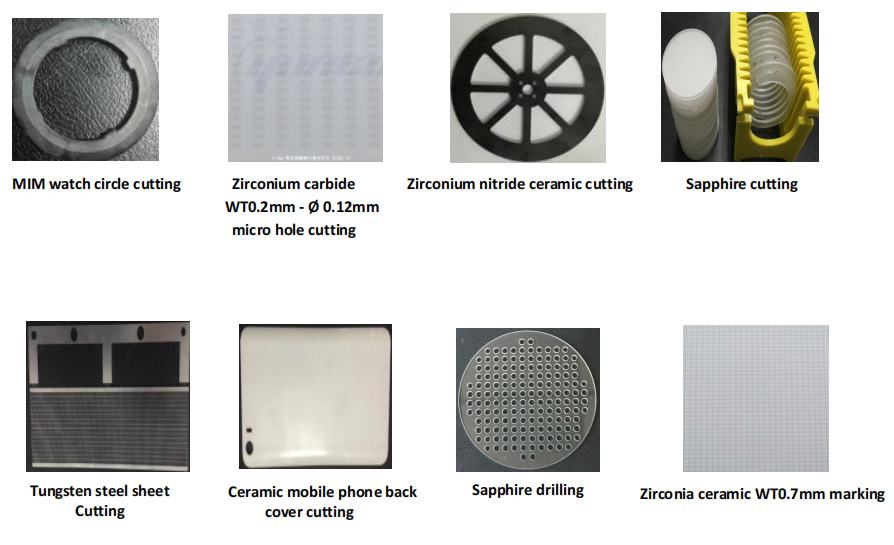

Hard and brittle material precision laser cutting machine is a kind of precision laser cutting machine, mainly used for cutting, drilling, slotting, scribing and other laser micromachining of hard and brittle material plane or regular surface equipment, such as MIM watch ring forming , Mobile phone back cover ceramic forming, ceramic plate slotting, sapphire drilling, tungsten steel sheet cutting and forming, zirconia ceramic scribing and drilling forming, etc. The equipment is advanced in design, equipped with open CNC software system, adopts modular function development technology, embedded laser processing technology library and multi-axis motion control system, with high openness, good stability and simple operation.

Technical Parameters

| Maximum operating speed | 1000mm/s(X) ;1000mm/s(Yl&Y2) ;50mm/s(Z); |

| Positioning accuracy | ±3um (X) ±3um (Y1&Y2) ;±5um (Z); |

| Repetitive positioning accuracy | ±lum (X) ;±lum(Y1&Y2) ;±3um(Z); |

| Machining material | Alumina & zirconia & aluminum nitride & silicon nitride & Diamond & Sapphire & Silicon & gallium arsenide & tungsten steel, etc; |

| Material wall thickness | 0~2.0±0.02mm; |

| Plane machining range | 300mm*300mm;(support customization for larger format requirements) |

| Laser type | Fiber laser; |

| Laser wavelength | 1030-1070±10nm; |

| laser power | CW1000W&QCW150W& QCW300W& QCW450W for option |

| Equipment power supply | 220V± 10%, 50Hz;AC 20A (main circuit breaker); |

| File format | DXF、DWG; |

| Equipment dimensions | 1280mm*1320mm*1600mm; |

| Equipment weight | 1500Kg; |

Sample Exhibition

օ Laser micromachining of ceramics, sapphire, diamond and calcium steel, high hardness & high brittleness plane and regular curved instruments

High precision machining

օ Small cutting seam width: 15 ~ 30um

օ High machining accuracy: ≤ ± 10um

օ Good quality of incision: smooth incision, small heat affected zone, less burr and edge chipping < 15um

օ Size refinement: the minimum product size is 100um

Strong adaptability

1.Have the ability of laser cutting, drilling, slotting, marking and other fine processing skills for plane & curved surface instruments

2.Can machine alumina, zirconia, aluminum nitride, silicon nitride, diamond, sapphire, silicon, gallium arsenide and tungsten steel

3.Equipped with a self-developed direct drive mobile double drive precision movement platform, granite platform, aluminum alloy granite beam for selection

4.Provide the optional function, such as double station & Visual Positioning & automatic feeding and unloading system & dynamic monitoring etc.

5.Equipped with self-developed long & short focal length, sharp nozzle & flat nozzle fine laser cutting head

6.Equipped with modular material receiving and dust removal pipeline system

7.Provide self-developed movable tension frame & fixed tension frame & vacuum adsorption & honeycomb plate, etc. optional fixture

8.Equipped with the self-developed 2D & 2.5D & 3D CAM software system for laser micromachining

Flexible design

1.Follow the design concept of ergonomics, delicate and concise

2.Flexible software & hardware function collocation, supporting personalized function configuration & intelligent production management

3.Support positive innovation design from component level to system level

4.Open control & laser micromachining software system easy to operate & intuitive interface

Technical certification

օ CE

օ ISO9001

օIATF16949

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur