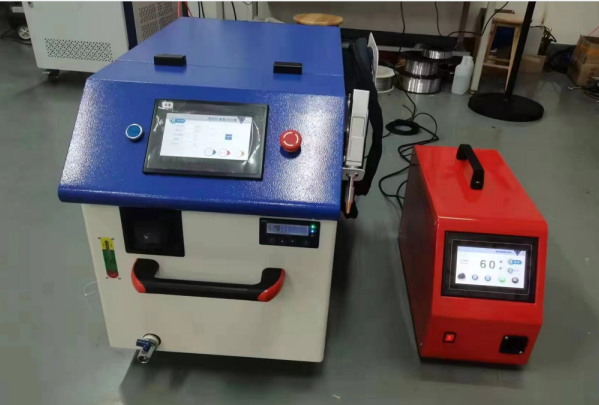

Professional manufacturers of hand-held laser welding machine long-term spot supply of hand-held laser welding machine, bracket laser cutting machine, laser pipe cutting machine and other kinds of laser cutting equipment and welding laser welding equipment, rich types, complete models, rest assured after sale. The following combination of years of experience for you to sort out the most practical handheld laser welding machine maintenance methods.

1. Regular detection: After the handheld laser welding machine equipment is put into use, regular detection should be done, such as whether the cooling fan rotation is smooth, whether there is abnormal vibration and sound, whether there is gas leakage, welding wire joints and military aid explosion whether there is peeling or lax, cable has abnormal heating problem, all inspection items found abnormal, immediately stop, repair.

2, regular dust cleaning: hand-held laser welding machine is forced air cooling, easy to inhale dust from the surrounding, so we should do regular inspection and clean up the dust inside the welding machine. Especially the transformer, reactance coil and the gap between coil joints should pay special attention to clean up.

3, check the wiring position regularly: power distribution into the force side, output side terminals, as well as the wiring position of internal and external wiring, each part of the wiring screw loose should be checked regularly, if the inspection finds rust parts to remove the rust to make the contact conductive.

4, the other is the annual inspection and maintenance of the handheld laser welding machine: Welding long-term operation use, sometimes the shell due to contact deformation, or damp rust, and internal parts with the work will kill, so in the annual maintenance and inspection to implement the replacement of defective parts and shell repair and insulation deterioration parts of the reinforcement and other comprehensive repair work, defective parts are recommended to replace all new products, to ensure the overall performance of the welder.

The above regular maintenance and inspection of the handheld laser welding machine should pay attention to, which can greatly reduce the occurrence of welding failures, but also increase the service life of the welding machine and the efficiency of the welding machine operation, but also improve the safety of the operation, so the handheld laser connector should pay attention to the usual maintenance and overhaul, More about laser welding machine and related equipment maintenance methods, welcome to our official website to understand!

Post time: Mar-07-2023