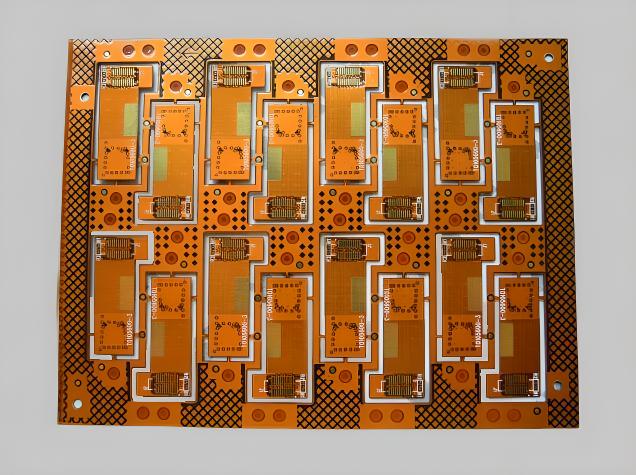

FPC is a flexible circuit board, also called a soft board, which is a type of PCB. FPC flexible circuit board has a very simple structure and is mainly used for connection with other circuit boards. Because FPC has the characteristics of continuous automated production, high wiring density, light weight, small size, few wiring errors, flexibility and elastic shape change, it is widely used in military industry, national defense and consumer electronics such as digital cameras. , watches, laptops, LCM and other fields. It is especially suitable for applications with complex circuits, high signal processing requirements, or special electrical or mechanical performance requirements.

Laser cutting is an important application technology on FPC flexible circuit boards. It is mainly used for FPC shape cutting, contour cutting, drilling and covering film window opening and other processes. The advantages of laser cutting of FPC flexible circuit boards are as follows:

Laser cutting has high precision, smooth surface, fast speed, small cutting slit width, and is not easy to deform; the laser focus spot is small, and after focusing, the laser can process the material into any complex shape; the power distribution is uniform, the thermal effect is small, and the cutting quality is high; it can also It ensures the verticality of the cutting surface and better compensates for the processing errors caused by FPC deformation; the processed FPC flexible circuit board has no carbonization phenomenon, which ensures its size and quality. It also supports multiple visual positioning features. Such as crosses, solid circles, hollow circles, L-shaped right-angled edges, image feature points, etc.

Men-Luck circuit board laser cutting machine uses a galvanometer and CCD positioning method. It has the advantages of small light spot, small cutting slit width, and small thermal impact. The whole machine has a simple structure, adopts ergonomic design concepts, and the control software interface is intuitive. , easy to operate, good stability and shock resistance, and higher file conversion speed. This equipment can meet various rigid requirements for cutting FPC flexible circuit boards and is the best choice for cutting flexible circuit boards.

Laser cutting technology has important application advantages in the production of FPC flexible circuit boards. Able to achieve accurate, efficient, stable and high-quality FPC cutting processing. These advantages make FPC flexible circuit board laser cutting technology an indispensable and important process in the field of electronic product manufacturing. As a professional laser cutting machine manufacturer, our company can provide cutting and proofing of a variety of circuit boards. If you have new product cutting needs, you can also make an appointment in advance. Men-luck can specially customize the equipment according to customer needs to meet various applications. micro-machining needs.

Post time: Dec-13-2023