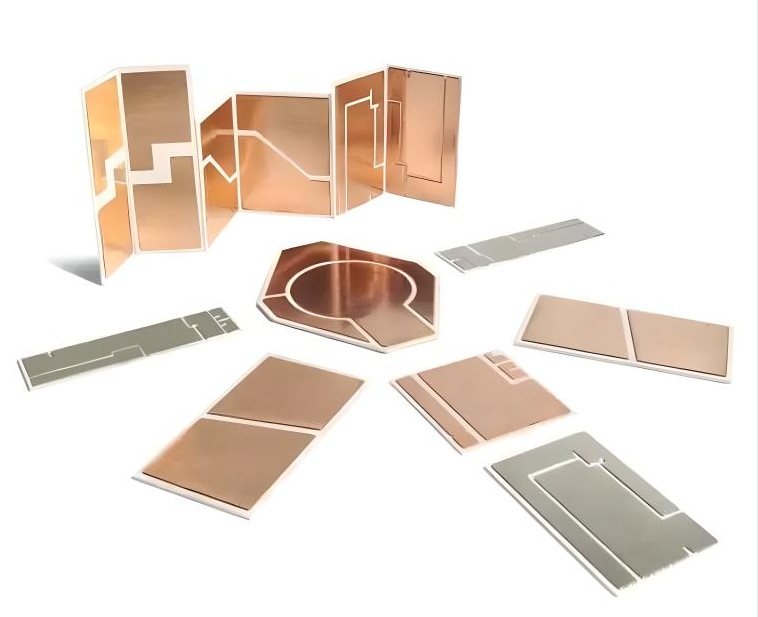

Electromagnetic film is an electromagnetic shielding material that can effectively isolate external electromagnetic interference and is mainly used in flexible printed circuit boards. The electromagnetic film is light in weight and resistant to bending, and can meet Xiankuban’s requirements for lightweight and flexibility. With the rapid development of the PBC industry, the FPC electromagnetic shielding film industry has also shown a rapid growth trend. At present, the usage rate of electromagnetic shielding film in FPC products has reached about 25% (the usage rate here is calculated based on the use area), showing its important position in the electronics industry. The high quality requirements of flexible circuit boards determine that the quality of the electromagnetic film must meet its accuracy and quality requirements. This also puts forward higher requirements for laser cutting machines.

The main advantages of laser cutting electromagnetic film:

High dimensional accuracy: The electromagnetic module is small in size, light in weight, and has high circuit density. It adopts laser cutting with high precision and small slit width, which can meet the product’s requirements for dimensional accuracy.

Good cutting effect: The laser cutting machine can achieve “cold cutting” when cutting the electromagnetic film, which will not cause the film material to turn yellow or black and cause performance changes. The incision is smooth and flat, ensuring product quality.

High cutting efficiency: It adopts a precision interactive workbench and is configured with automatic/manual working modes, which can realize automatic loading and unloading to meet customers’ multi-station production automation needs, thus improving production efficiency.

High performance: Using imported purple laser, the beam quality is high and the spot is delicate, which can realize ultra-fine cutting, drilling and marking, ensuring the processing quality of the product.

Environmental protection and safety: The fully enclosed safety frame protects the safety of operators and meets environmental protection requirements.

Low operating costs: The machine is simple to operate, requires no additional consumables, and has low power consumption, reducing production and operating costs.

According to the above introduction by laser cutting machine manufacturer men-luck, laser cutting of electromagnetic films can meet the high-performance, high-quality, high-efficiency, and high-processing requirements of FPC products. It is an indispensable laser micro-machining technology in the FPC industry. As a professional laser cutting machine manufacturer, we have a wide range of laser cutting machines that can meet the processing needs of various materials and applications. If you need to test, you are welcome to provide materials for proofing. We can also make equipment according to customers’ processing needs. Special customization to meet customers’ actual application processing needs, please call us for more information.

Post time: Dec-15-2023