The Indian laser micro-cutting machine has been completed after sale, the production of the stent has been normally carried out, the equipment is running well, and the new material stent is about to be prepared for production, but suddenly sent a technical support request. Where is the problem, come and see the manufacturer men-luck is how to follow up.

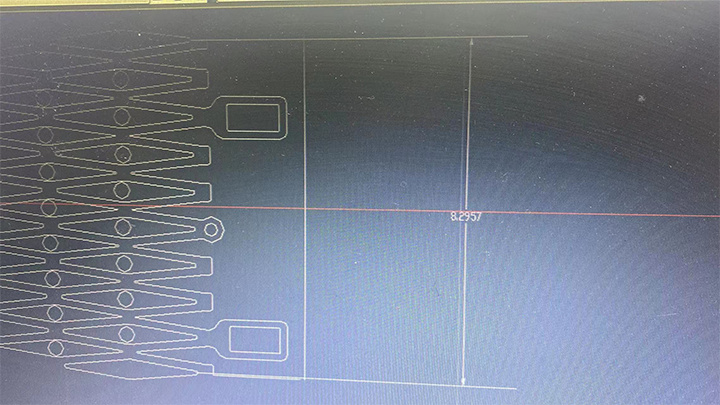

After the customer replaced the nickel-titanium stent tube, there was a problem in equipment debugging. We need to assist in parameter debugging according to the stent drawings provided by the customer to ensure that the new support can be cut normally. Our engineers carefully checked the drawing and found that the drawing was incomplete, so they redrew the drawing. Due to the replacement of pipe raw materials, diameter data is not the same, the bushing and chuck on the laser cutting machine equipment should be replaced, the cutting height also needs to be re-debugging, after remote three remote focus debugging and laser energy debugging, theoretically cutting should be normal.

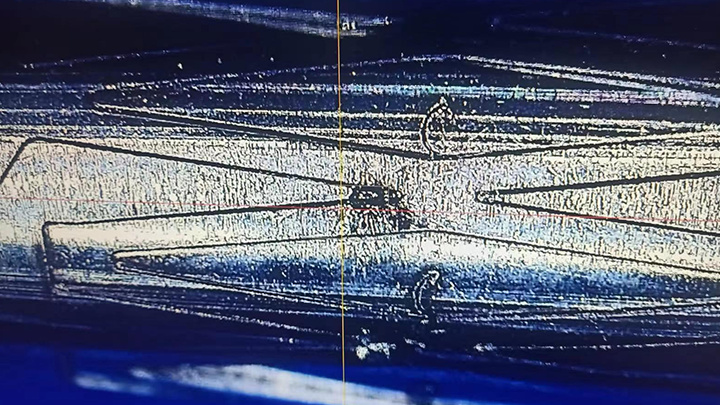

However, a new problem occurred in the process of test cutting, the raw material could not be cut completely. After careful measurement and comparison with the drawings, the engineer found that the diameter width of the support was 0.04mm smaller than the actual size. The diameter width data provided by the customer was 2.6mm, but the actual size was 2.64mm (Figure 1 of the support), so the tube could not be cut normally, and the 0.04 error was also detected by the equipment. After the diameter data is adjusted, the problem of cutting nickel-titanium stent is easily solved.

After continuing the test cutting, it was found that there were patches at the lower knife position of the stent (Figure 2). After adjusting the cutting height and laser energy again, most of the patches were gone, and there was still a small amount of patches in one place (Figure 3). After fine-tuning the laser energy again, the patches disappeared, and the 2.64mm diameter stent was successfully cut perfectly.

At present, the nickel-titanium stent has been mass-produced to provide high-quality services for more users with cardiovascular diseases. As a precision medical laser micromachining equipment service provider, we will combine the market demand, continue to sum up production experience, and develop more intelligent, efficient, higher precision cardiovascular stent micromachining equipment and perfect stent cutting technology solutions.

Post time: Sep-05-2023