Featured

High Quality OEM Fiber Welding Factories - Popular Design for Better OEM Bending Sheet Metal Laser Cutting Part Factory Price – Jingyuzhou

High Quality OEM Fiber Welding Factories - Popular Design for Better OEM Bending Sheet Metal Laser Cutting Part Factory Price – Jingyuzhou Detail:

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Popular Design for Better OEM Bending Sheet Metal Laser Cutting Part Factory Price, Always for the majority of business users and traders to provide best quality products and excellent service. Warmly welcome to join us, let’s innovation together, to flying dream.

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for China Metal Casting Part and Metal Cutting Part, Our tenet is “integrity first, quality best”. Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

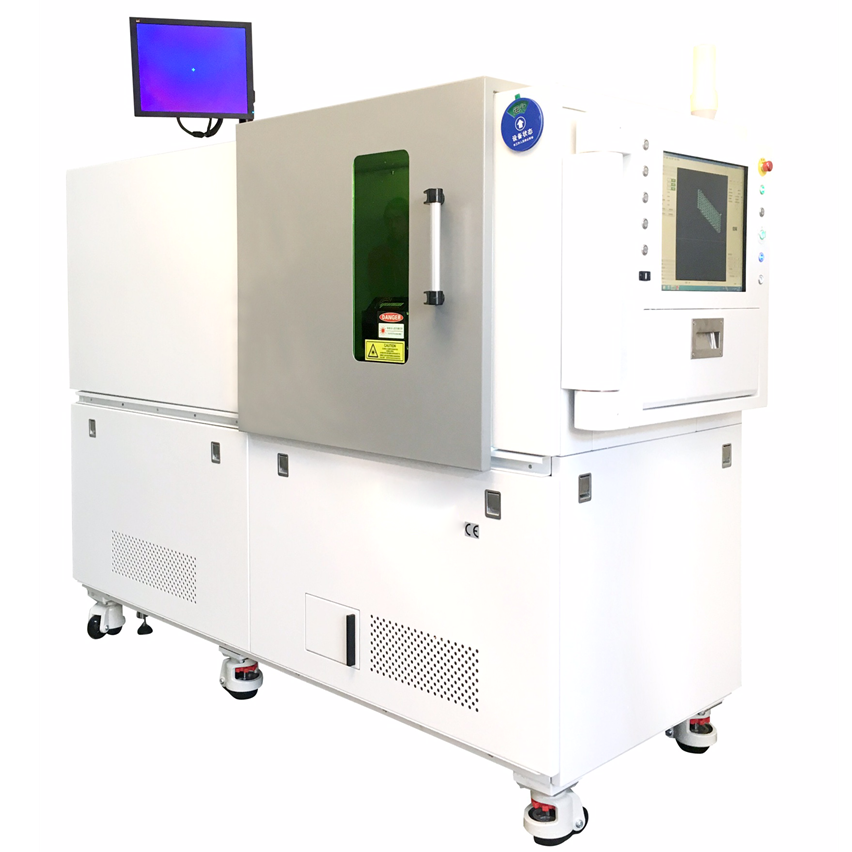

YC-SLC300

Technical Parameters:

| Maximum operating speed | 300mm/s(X) ;100mm/s(Y)for option ;100mm/s(Z);600rpm(θ) |

| Positioning accuracy | ±1um(X);±3um(Y)for option;±3um(Z);±15arcsec(θ); |

| Repetitive positioning accuracy | ±0.2um(X);±1um(Y)for option;±1um(Z);±3arcsec(θ) |

| Cutting seam width | 15um~25um |

| Consistency of reinforcement width | <±5um; |

| Machining material | 316L & Ni-Ti & L605 & Fe & Mg & Zn and other alloy materials |

| Tube blank length | <2.5m (customized support fixture) |

| Processing wall thickness | 0~0.3±0.02mm; |

| Processing pipe diameter | Φ0.1~Φ7.5±0.02mm; |

| Single processing range | 0~300mm (longer products will be machined by segmented splicingmethod); |

| Laser type | Fiber laser; |

| Laser wavelength | 1030-1070±10nm; |

| laser power | 100W&200W&300W for option; |

| Equipment power supply | 220V± 10%, 50Hz;AC 20A (main circuit breaker); |

| File format | DXF、DWG; |

| Equipment dimensions | 2000mmx1000mmx1600mm; |

| Equipment weight | 1500Kg; |

Sample Exhibition:

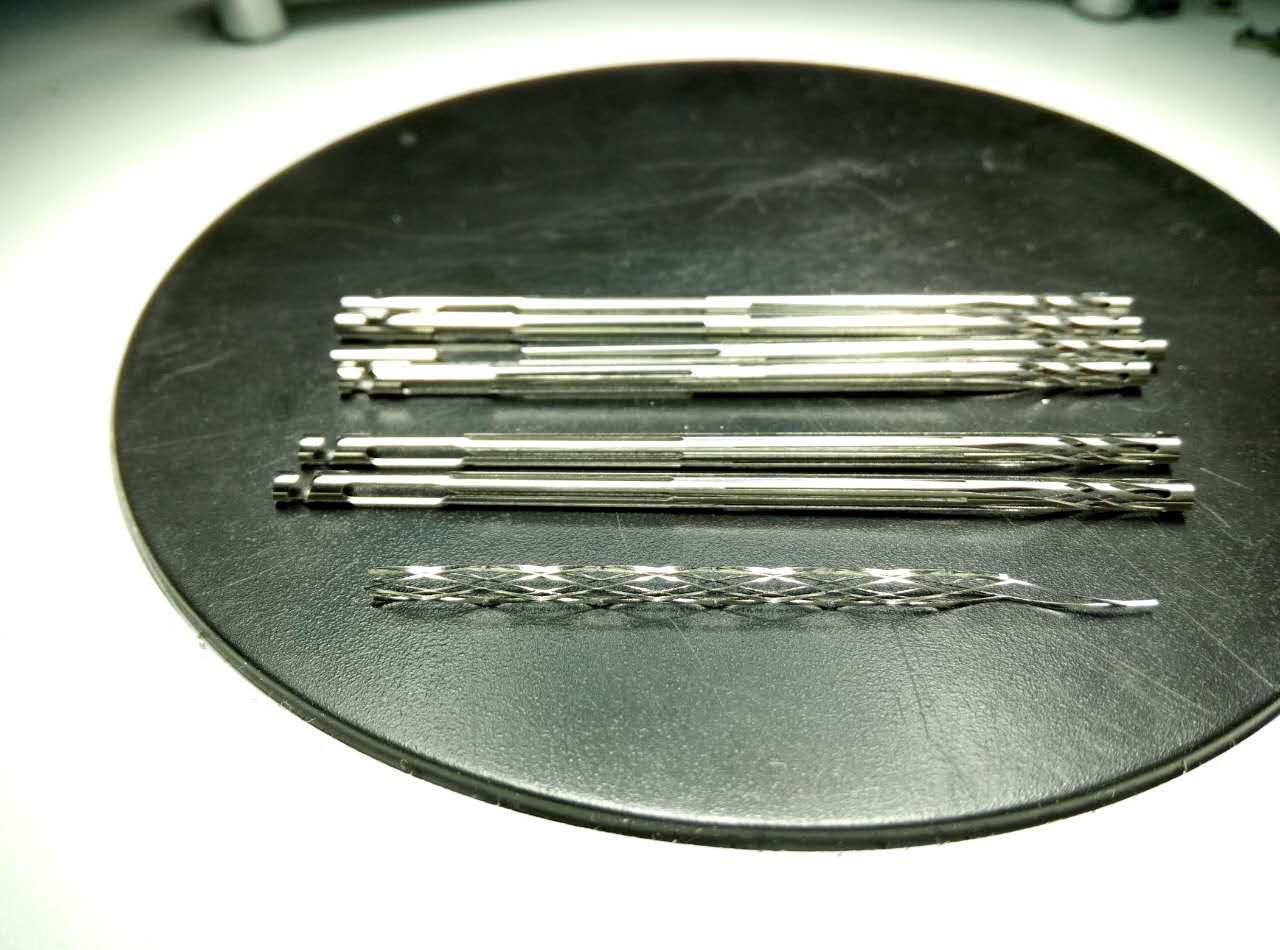

316L & L605 bare

metal coronary stent

Ni-Ti- Φ 2.7mm-

WT0.2mm coronary stent

L605- Φ1.8mm-WT0.15mm

drug coated coronary stent

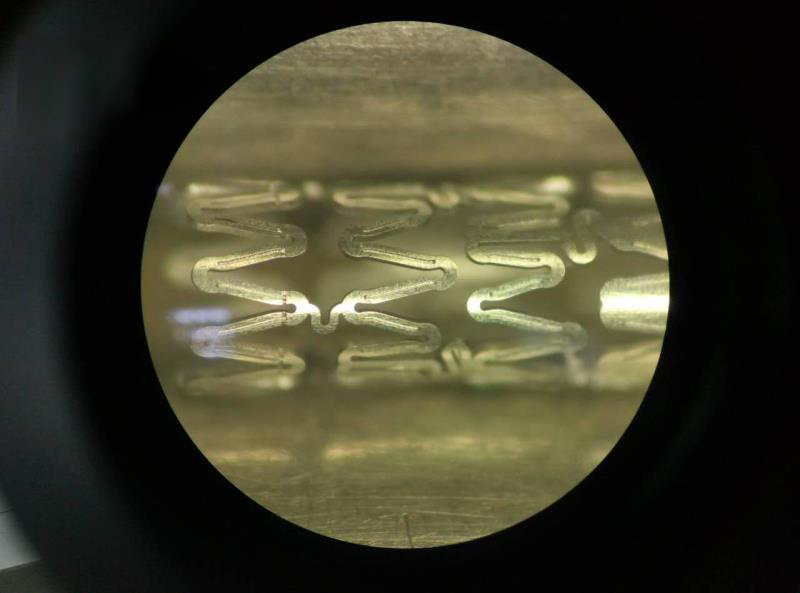

microstructure

Ni-Ti- Φ 2mm-L100mm

-WT0.2mm coronary stent

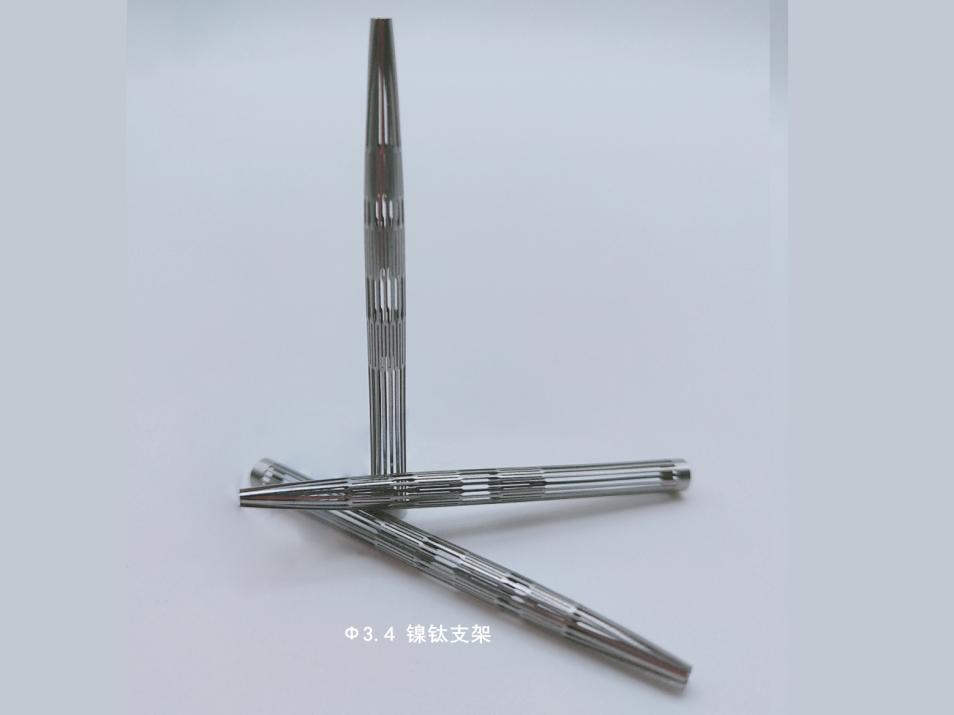

Ni-Ti- Φ 3.4mm-WT0.2mm

coronary stent

Φ2.03mm-WT0.2mm

venous filter microstructure

Application scope

օ Laser micromachining of bare metal stent and drug coated stent such as coronary artery stent and vein filter

High precision machining

օ Small cutting seam width: < 20um

օ High machining accuracy: ≤ ± 5um

օ Good quality of incision: no burr & smooth incision

օ High machining efficiency: one-off cutting through one side pipe wall & continuous automatic feed machinin

Strong adaptability

օ Have the ability of laser dry cutting & wet cutting & drilling & blind slotting and other fine machining technology

օ Support the centripetal, vertical and compound opening feature machining of equal diameter tube, variable diameter tube and plane instrument

օ Can machine 316L & Ni-Ti & L605 & Fe & Mg & Zn and other alloy materials

օ Compatible with precision D-type chuck & ER series chuck & three-jaw chuck and other precision thin-walled tube clamping system

օ Adopt the combined precision thin-walled tube shaft sleeve support system with self-adaptive shape tolerance variation

օ Provide the matching scheme of precision thin-walled tube continuous automatic feeding machining & dry / wet cutting and sealing material receiving

օ Equipped with self-developed 2D & 2.5D & 3D CAM software system for laser micromachinin

Flexible design

օ Follow the design concept of ergonomics, delicate and concise

օ Equipped with machine vision system to real time online monitor the laser dynamic machining process

օ The software and hardware functions match flexibly, support personalized function configuration & intelligent production management

օ Support forward innovative design from component level to system level

օ Open type control & laser micromachining software system is easy to operate & intuitive interface

Technical certification

օ CE

օ ISO9001

օ ISO13485

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Popular Design for Better OEM Bending Sheet Metal Laser Cutting Part Factory Price, Always for the majority of business users and traders to provide best quality products and excellent service. Warmly welcome to join us, let’s innovation together, to flying dream.

Popular Design for China Metal Casting Part and Metal Cutting Part, Our tenet is “integrity first, quality best”. Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for High Quality OEM Fiber Welding Factories - Popular Design for Better OEM Bending Sheet Metal Laser Cutting Part Factory Price – Jingyuzhou , The product will supply to all over the world, such as: Amsterdam, Serbia, Iraq, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.