Hand held laser welding

Three-in-one handheld laser welding machine

Three-in-one handheld laser welding machine description

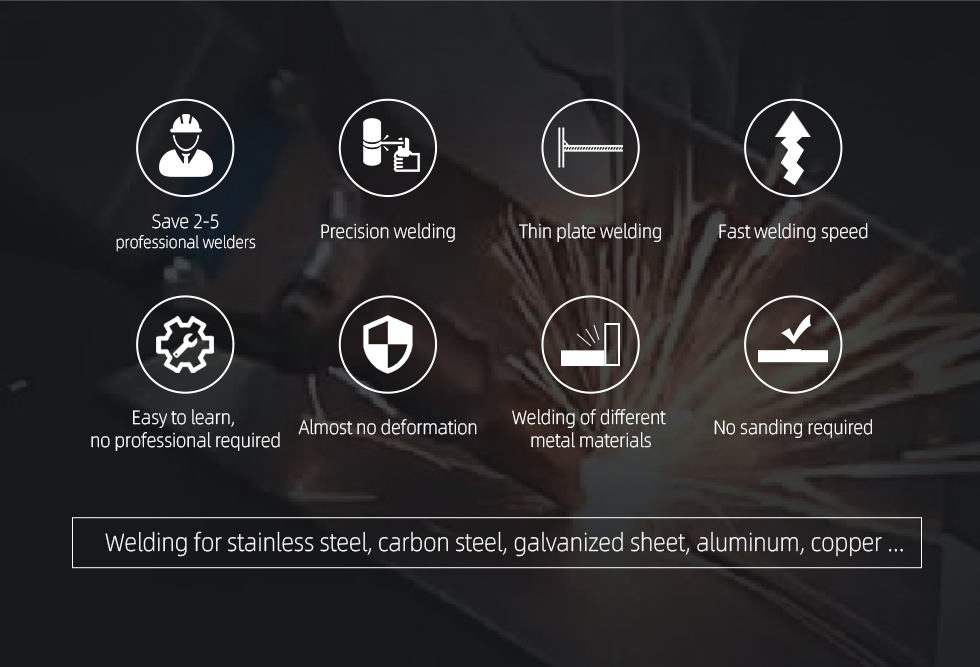

The three-in-one hand-held laser welding machine is referred to as three-in-one hand-held welding or hand-held welding. This product is a lightweight, portable, easy-to-operate, economical and intelligent innovative product. Integrated design of button and handle, easy to use. The built-in scanning system uses small high-speed motors and drivers. The main body is processed and formed as a whole, which is strong and dustproof, stable and durable. For common materials and thicknesses, the system comes with a process parameter library, which simplifies tedious processing and improves processing efficiency. Can be used for cleaning, cutting and welding work. There is no need to replace the machine, one machine is multi-purpose, convenient and fast, and effectively saves production costs. Switch cleaning, welding and cutting according to different scenarios, convenient and easy to operate.

Production of Sanhe One Hand Welding

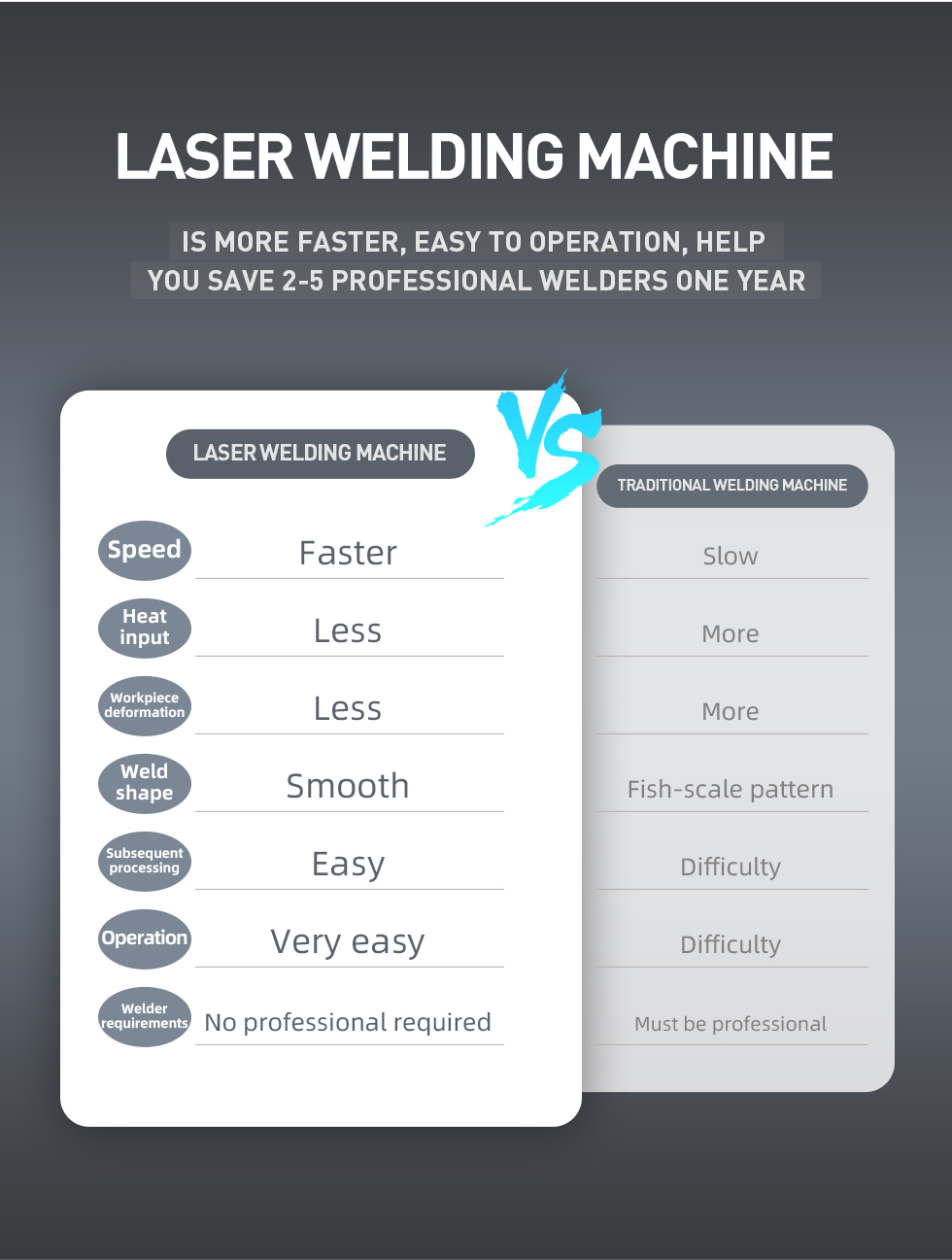

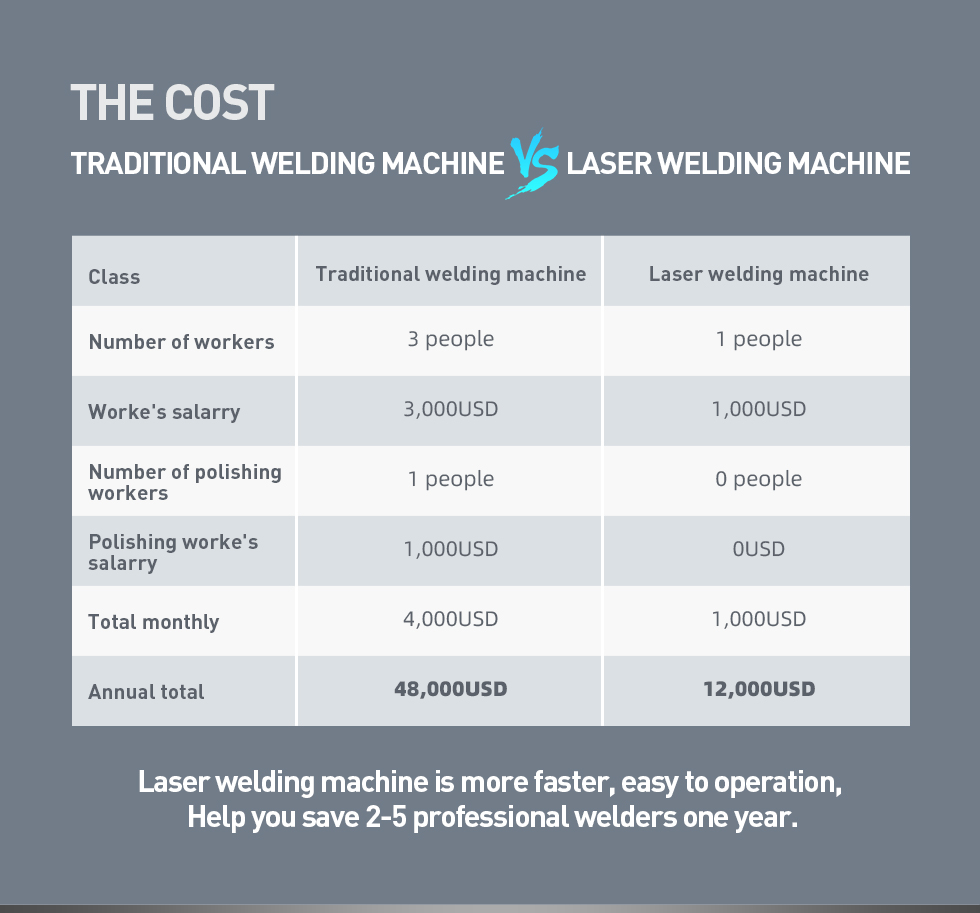

In metalworking operations, cutting, welding and cleaning are often closely linked with upstream and downstream operations. The traditional operation method often requires three different operating equipment to carry out three processes. Not only is the procurement cost high, the operation efficiency is not high, but also there are a series of problems such as complicated steps and large space occupation. In response to this pain point, to provide more efficient and flexible solutions for the market, to provide customers with integrated solutions, and to launch a handheld laser cutting, cleaning and welding machine!

Machine features

1. Small size, high portability, easy maintenance and debugging.

2. The laser head is light, and the handle conforms to the ergonomic mechanics of the human hand, which can be easily operated with one hand.

3. Fast heat dissipation.

4. Low failure rate.

5. Long service life.

6. Equipped with automatic safety protection devices to protect personal safety at all times。

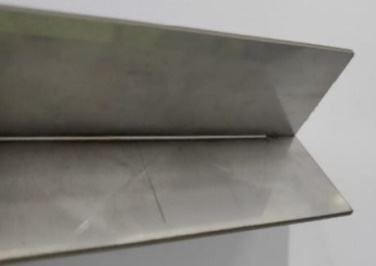

7. No welding scars, beautiful and smooth welded joints.

8. Simple operation,you can get started quickly even without any experience.

9. Easy maintenance and simple maintenance.

10. Using industrial computer to control the speed, power, heat, etc. of laser and welding, the operation is more simple, reliable and easy to control, and can be widely used in many places.

11. Our optimized optical and water-cooling equipment can make the laser head work stably for a long time.

12. The industrial computer is used to control the speed, power, heat, etc. of laser and welding. The operation is simpler, more reliable, and easier to control. It can be widely used in many places.

13. The welded joint structure can be freely selected, and the weld width can be adjusted to fully meet your different requirements for cost and site.

14. Movable castors for outdoor welding.

15. Welding meeting any angle/shape.

16. The laser head is light, and the handle conforms to human engineering mechanics, which can be easily operated by one hand.

17. The system has high flexibility, can be compatible with multiple models, and has short conversion time.

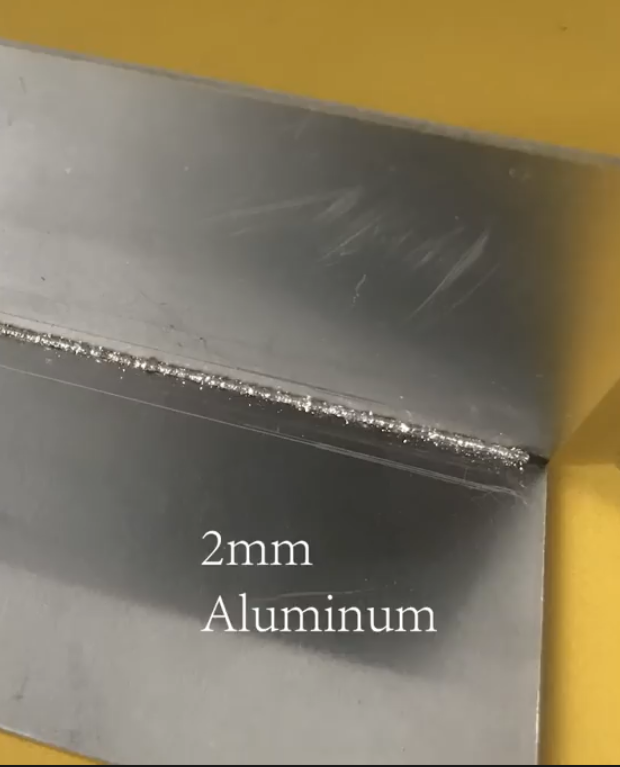

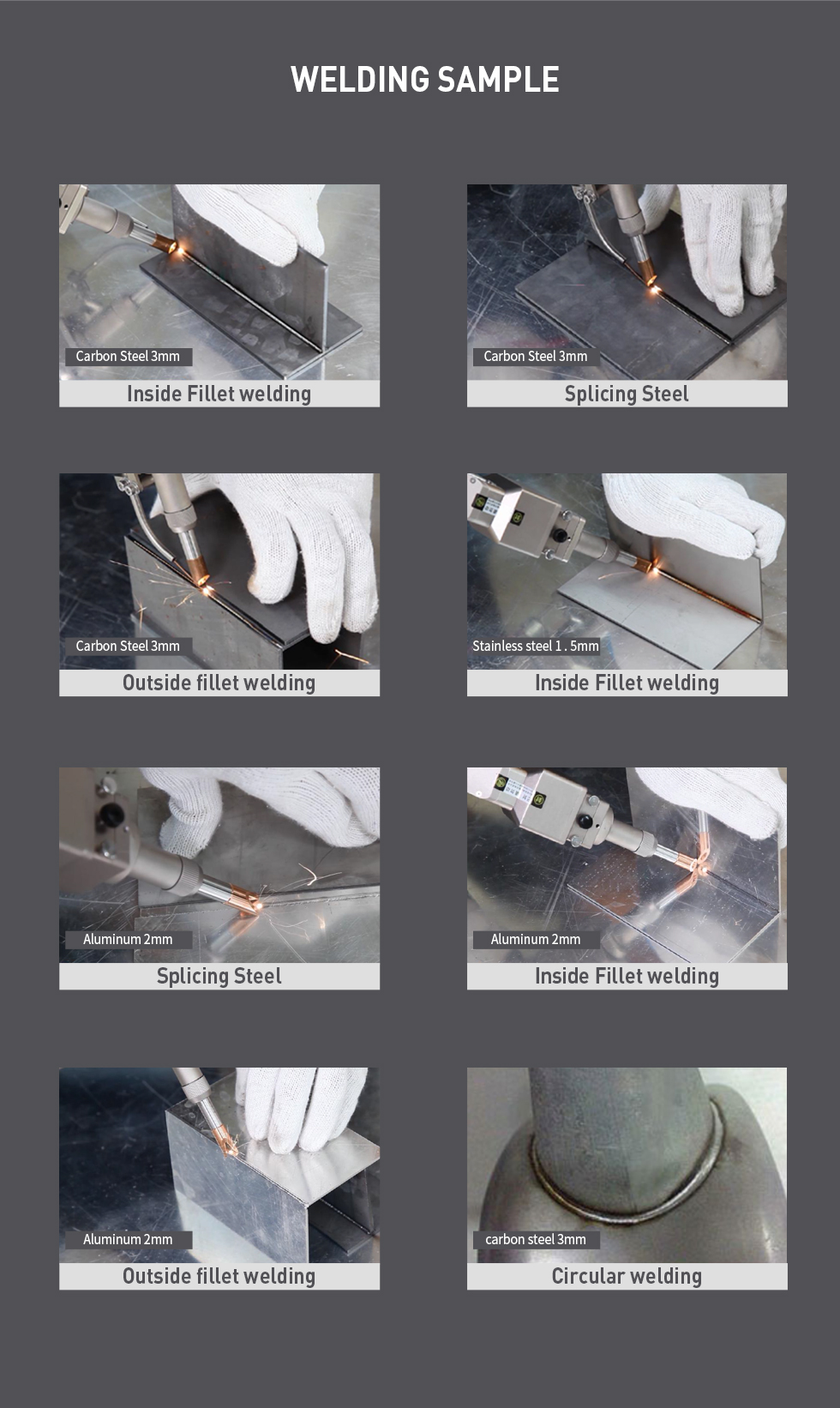

Sample

Mainly for large and medium-sized sheet metal, cabinets, chassis, aluminum alloy door and window frames, stainless steel wash basins and other large workpieces for fixed positions such as inner right angles, outer right angles, plane welds. During welding, the heat-affected zone is small, the deformation is small, and the welding depth is large, and the welding is firm. Widely used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel product industry, stainless steel engineering industry, door and window industry, handicraft industry, household goods industry, furniture industry, auto parts industry, etc.

Mainly for large and medium-sized sheet metal, cabinets, chassis, aluminum alloy door and window frames, stainless steel wash basins and other large workpieces for fixed positions such as inner right angles, outer right angles, plane welds. During welding, the heat-affected zone is small, the deformation is small, and the welding depth is large, and the welding is firm. Widely used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel product industry, stainless steel engineering industry, door and window industry, handicraft industry, household goods industry, furniture industry, auto parts industry, etc.

Handheld welding video

Technical parameters

|

Model |

MEN |

|

Power |

1000W-3000W |

|

Laser Wavelength |

1080±5nm |

|

Fiber length |

10m |

|

Optical fiber core diameter |

50um |

|

Seams Requirements |

<1.6mm |

|

Rcommended Material Thickness |

0.5-8mm |

|

Overall Dimensions(L*W*H) |

840mm*490mm*670mm |

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur