Machinery

Automatic loading and unloading laser pipe cutting machine with three chucks

| Pipe length | 6000mm / 8000mm / 12000mm |

| Pipe diameter | 20mm-200mm / 30mm-630mm |

| Feeding size | 800mm*800mm*6000mm / 800mm*800mm*8000mm |

| laser power | 1000W/1500W/2000W/2500W/3000W/4000W |

| Applicable pipe type | Round pipe, square pipe, rectangular pipe, elliptical pipe, D-type, T-type, H-type steel, channel steel, angle steel, etc |

| Applicable materials | Stainless steel, carbon steel, galvanized pipe, copper pipe, aluminum pipe, aluminum alloy |

| Laser brand | Nlight / IPG / Raycus |

| load | 25 kg / M |

| Repeat positioning accuracy | ±0.03mm |

| Acceleration | 1.5g |

1. Round pipe, rectangular pipe, fully automatic feeding, super large bundle feeding, maximum weight 2.5T.

2. Advanced chuck clamping system, chuck self centering, adjust the size of the clamping force according to the profile specification, provide a full set of solutions for thin-walled pipe, the maximum speed up to 150rpm, chuck is sealed, prevent cutting scrap iron into the interior, stable and reliable.

3. The floating lifting material support, the support height can be adjusted automatically and in real time, according to the state change of the pipe, to ensure that the bottom of the pipe is always inseparable from the top of the support shaft, and act as dynamic support of the pipe.

4. The automatic receiving device can follow the lifting support, catching the material and put into the basket; the floating support is controlled by servo motor, which can adjust automatically according to the pipe diameter quickly, saving clamping time, ensuring concentricity and reducing pipe shaking.

5. Welding seam identification can set the welding seam position of the pipe, to ensure that the start cutting position is away from the weld during processing, so as to avoid the problem of hole blasting at the weld.

6. 0 tailing cutting wtih three chucks, combined with cutting head offside cutting and groove process, to achieve tailing within 50-80mm.

7. Simple operation of nesting system, saving labor costs, so that graphics no longer trouble customers.

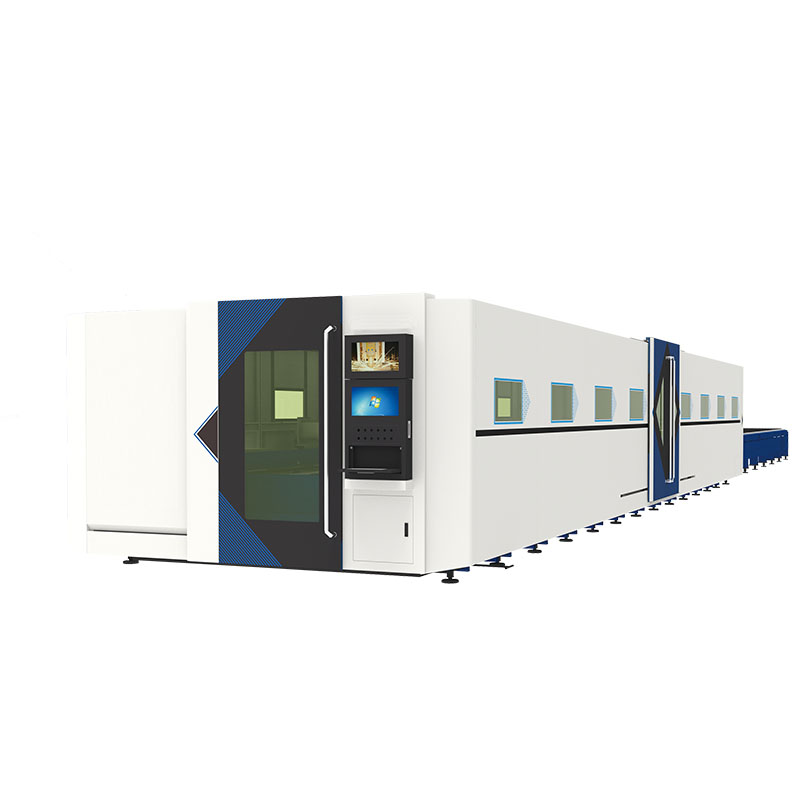

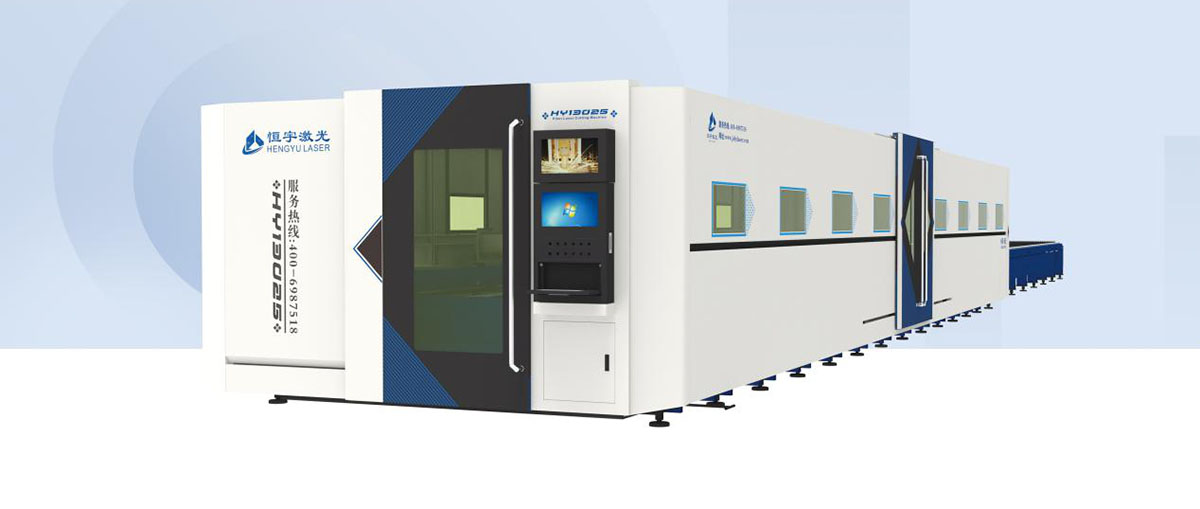

1. Positioning in high-power, solid bed, well-designed, cutting thick metal plate and non-ferrous metal, acceleration 1.5g, can cut 35mm steel plate, 50mm stainless steel plate and 12mm aluminum plate at high speed.

2. 3 meters, 4 meters, 6 meters and 8 meters climbing type exchange table, fast exchange, improve efficiency.

3. Fully covered structure, to provide personal safety protection, and to avoid injury caused by invisible light radiation and mechanical movement of the machine. The equipment can be emergency braking to prevent electric shock.

4. Steel plate welding, high temperature annealing, vibration aging, detachable bed, low maintenance cost.

5. Imported rail and servo motor reducer, reducer with flange connection, rail rack with double lubrication.

6. The laying plane of the guide rail is a whole piece of steel plate, one time positioning processing by CNC machine tool, so as to ensure the accuracy. The high-density stop block is installed, and it will not deform even after a long time.

7. The precision of the reducer which imported from Germany can reach 3-1 arc minutes, the eccentric disk installation mode and the gear flange output mode are stable and durable.

Related news

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur