Handheld laser welding as a laser processing technology, laser welding technology has been applied to the welding of small thin parts as early as 1964. With the rapid development of the automobile industry and the continuous improvement of people’s needs, to meet the requirements of safety, environmental protection, and energy conservation, and to achieve the automation, flexibility and intelligent development of welding product manufacturing, laser welding technology has been applied to the field of automobile body manufacturing since the 1980s. According to relevant statistics, 50%~70% of auto parts in developed European and American industrial countries are processed by laser, mainly laser welding and cutting. Laser welding has become a standard process in auto production.

Process principle

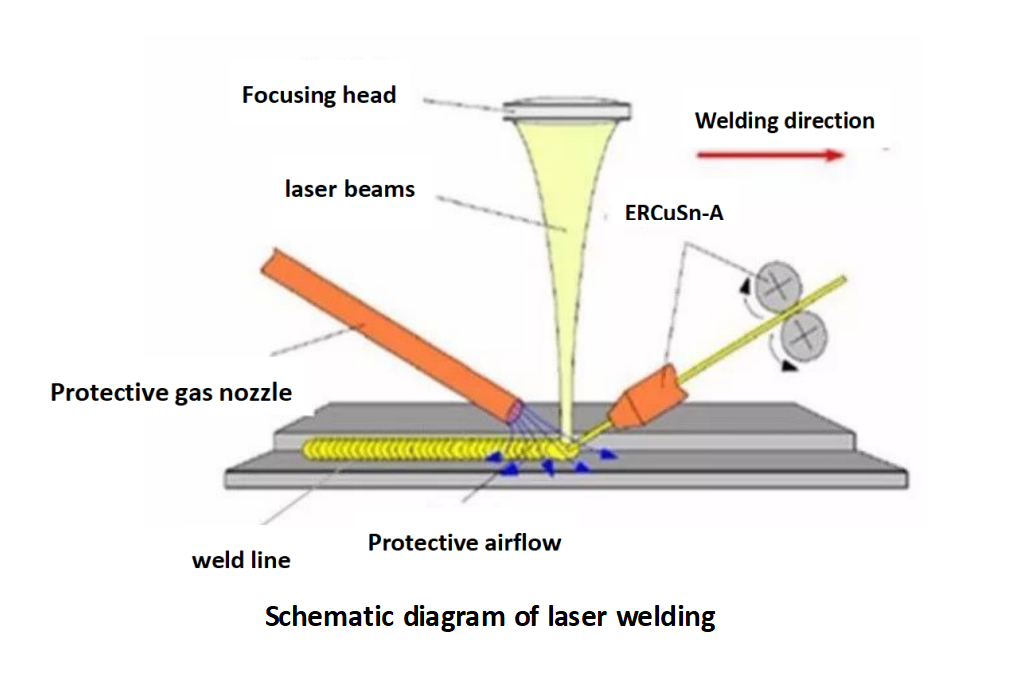

The principle of laser welding is that the laser beam emitted by the laser generator is focused on the surface of the welding wire for heating so that the welding wire is heated and melted, the steel plate on the vehicle body is wetted, the gap between the steel plate joints is filled, and the welding seam is formed to finally achieve a good connection. The brazing connection between copper welding wire and steel plate is formed after welding. The copper welding wire and steel plate are different elements, and the welding layer formed by them is the fusion of two different elements after high temperature. Compared with traditional spot welding, this welding method has better welding quality, faster speed, and higher strength of the welding part.

The advantages of laser hand-held welding are as follows:

1.Small heat affected zone. The input heat can be reduced to the minimum required amount, and the heat affected zone is small, so the thermal deformation is minimum.

2.Contactless. Visible welding, non-contact welding, no need to use electrodes, no concerns about electrode pollution or damage, and the consumption and deformation of the machine can be minimized.

3.The laser beam is easy to focus, align and be guided by optical instruments, can be placed at an appropriate distance from the workpiece, and can be guided between machines, tools or obstacles around the workpiece.

4.The laser beam can be focused on a very small area and can automatically weld small and closely spaced parts.

5.It is easy to realize high-speed automatic welding by numerical control.

Post time: Dec-23-2022