In recent years, there have been a lot of celebrities on the Internet, with countless fans, who speak in unison, and are known as “online celebrity”. In the past two years, if we want to say that online celebrity in the field of laser welding is “handheld laser continuous welding machine”! So today, let’s take a look at the hard journey of the development of this online red product.

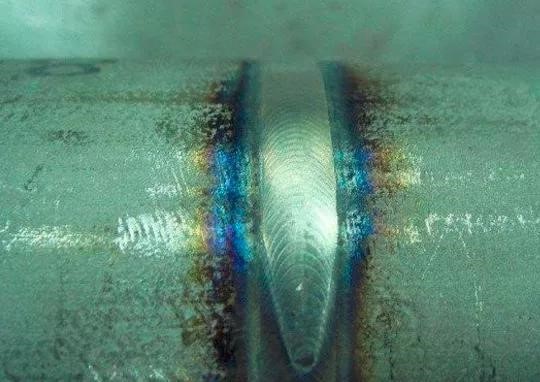

As we all know, laser has the characteristics of “good monochromaticity, high directionality, high coherence and high brightness”. Laser welding is also a process that uses the light emitted by the laser to focus the laser beam after optical processing, and generates a beam of huge energy to irradiate the welding part of the material to be welded, so that it can melt and form a permanent connection.

More than ten years ago, the main laser used for laser welding in China was solid-state lamp pumped laser. Its energy consumption and volume were large. In order to solve the disadvantages of its light path direction not easy to change, optical fiber transmission laser welding equipment was introduced. Then, inspired by foreign handheld optical fiber transmission equipment, we produced our own handheld laser welding machine.

This is the “first generation of handheld laser welding machine” in China. Due to the flexible transmission of optical fiber, the welding equipment has been greatly improved in terms of operation convenience.

So which was better at that time, “the first generation of hand-held laser welding machine” or argon arc welding? Everyone likes to ask. In fact, strictly speaking, these are two types of equipment. Their working principles are different, and they cannot be compared simply. They can only be said to have their own applications. Let’s take a look at the applicable occasions.

Advantages of manual argon arc welding:

1. Low price and small size;

2. It is more suitable for welding of materials above 1 mm;

3. High welding strength, suitable for most materials;

4. Large welding spot and beautiful appearance.

Disadvantages of argon arc welding:

1. The heat affected zone is large and easy to deform;

2. It is easy to produce plates less than 1mm

Defects

3. Arc light and waste smoke are harmful to human body.

Therefore, manual argon arc welding is more suitable for the welding of medium thickness plates and structural parts with certain strength requirements. If you want to obtain a right angle weld at the edges and corners of thin plate welding, the workload of polishing in the later stage will be relatively large, and it is easy to produce welding defects.

Post time: Feb-04-2023