Development history of handheld laser welding ——-the third generation handheld laser welding machine( 2)

At present, there are two main ways to swing the welding head of the “third generation handheld laser welding machine”: one is the galvanometer type, and the other is the rotary type.

Galvanometer type

Rotary type

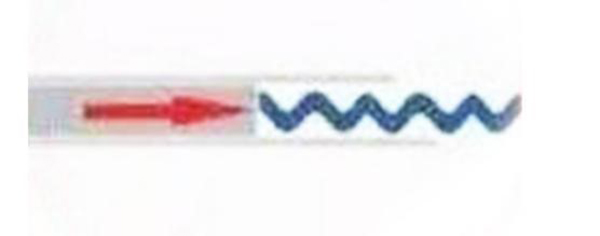

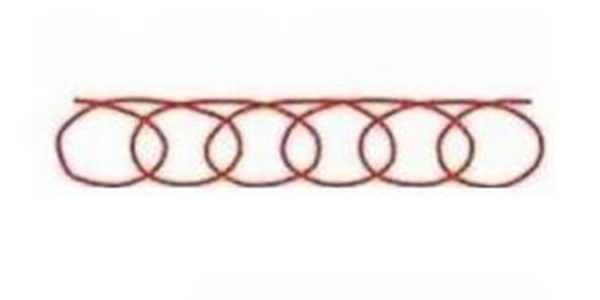

If the swing frequency is reduced and a straight line is welded manually, the two welding methods will present the following two different tracks, as shown in the following figure:

Galvanometer type

Rotary type

For example, if manual welding is compared to manual sewing of clothes, the galvanometer type and the rotary type are just like two kinds of stitches, which can sew clothes well. It is only a matter of opinion which is easy to use.

|

Galvanometer swing mode |

Rotary swing mode |

|

|

volume |

Slightly larger |

Slightly smaller |

|

weight |

Slightly heavier |

Slightly lighter |

|

Flare adjustment |

It can be adjusted directly on the control panel |

Need to replace the hardware to adjust the size |

The following is a case of the field application of Chuangheng Laser “the third generation handheld laser welding machine”:

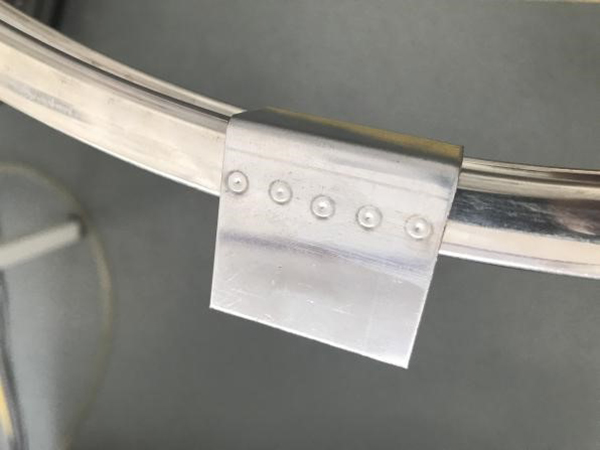

Welding of automobile seat structure

The strength of penetration spot welding is better than that of argon arc welding

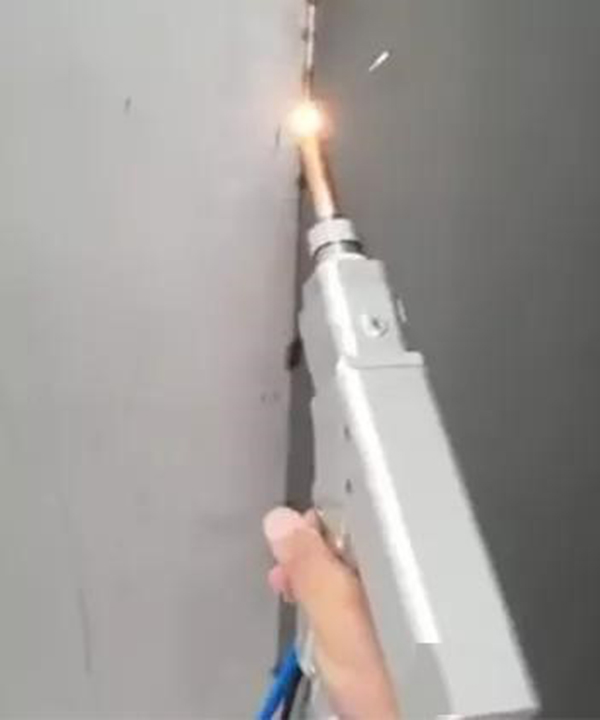

Exhaust funnel welding

Kitchen and bathroom welding

Do you think it is not easy to see online celebrity here, and you have made your own efforts. In 2020, Chuangheng Laser will continue to make efforts to test the fourth generation of products (wire feed handheld welding).

However, the author always has his own worries about this product. Hand-held laser welding belongs to the fourth category of laser products. Although the equipment has the function of grounding protection, it is hand-held welding after all. During welding, there will be a certain angle between the welding head and the workpiece surface, so that a part of the laser will be reflected by the material, especially for welding aluminum and copper, which are highly reflective materials. Therefore, operators should still have a separate operating space and wear laser goggles.

Protective mask worn by foreign operators

Finally, analyze the development direction of handheld laser welding. If you want to achieve a wider range of processing, you must also reduce the volume of the equipment. At present, the volume of the welding head is still too large. Some small spaces are not easy to operate, and climbing operation is not convenient.

At present, the market price of 1000 W hand-held swing welding is around 80000, which is still difficult for general customers to accept. In terms of security, it is also the most important thing to pay attention to at present. If the required welding power exceeds 1500 W, it is recommended to select automatic laser welding equipment with protective cover

Post time: Feb-13-2023