In the laser processing industry, cutting and carving are a higher frequency compared to welding and carving, at least 60%of laser machining. Laser cutting is not only the most advanced of all cut types, but also the highest cutting quality and cutting efficiency, but also various flexible cutting and alien cutting can meet the requirements of the cutting process.

According to the cut dimension, the laser cutting machine cutting method can be divided into three -dimensional cutting and plane cutting.

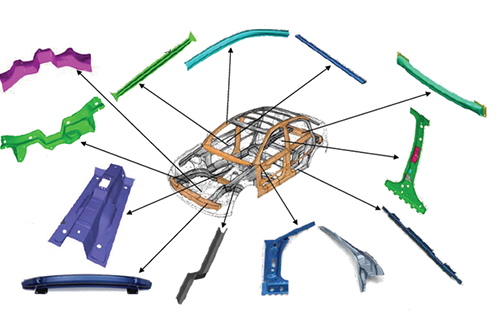

In terms of automotive body materials, such as high -strength steel structure components, laser cutting is undoubtedly the most accuracy, the best quality, and the highest efficiency of cutting, because whether it is plane or complex curved surface, laser cutting is not a problem. The heavy -duty cutting and lightweight processing that cannot be replaced by traditional knife cutting can be achieved. It is as large as the collision beam, front and rear bumper, B -pillar, the top beam of the car, suspended fixed rack, small to the car central control glass, rearview mirror glass, audio speaker network, electronic circuit board and other body, as well as the key to each composition site The location, the material is lighter or more intensive, and the traditional cutting knife cutting process is more complicated. For example, the cutting surface and the traditional cutting method of punching parts require two or three processes to complete. Another example is the audio speaker net, using laser cutting, uniform cutting holes, smooth, fast speed, relatively small loss, simple craftsmanship, and lower cost.

The application of laser cutting on the car airbag. The airbags are the same as the seat belt, providing safety guarantees for drivers or occupants. The laser -cut airbags are accurate size and seamlessly connected. The safety protection rate of airbags.

The application of laser cutting on the interior of the car is mainly cushions, seat sleeves, carpets, large surrounding pads, brake hoods, gear hoods, etc. The interior size of laser cutting is more accurate, and it is easier to disassemble, clean and clean. Laser cutting can be cut quickly to effectively improve processing efficiency.

With the continuous development of laser cutting technology and higher requirements for the quality of car experience, it can be said that more and more component cutting on cars use laser cutting. This is the irreplaceable advantage of laser cutting relative to traditional craftsmanship. High accuracy, fast speed, good cutting surface quality.

As a professional manufacturer of laser cutting machine, our laser cutting machine is mainly based on the different cutting materials and laser cutting machines and tube laser cutting machines. According to the laser type, our laser cutting machine mainly includes fiber laser cutting machines and flying. The second laser cutting machine, according to the different application industry, our cutting machine can be used for medical devices, 3C electronic structures, semiconductor integrated circuits. We consult and negotiate business.

Post time: Oct-20-2023