The drive motor of electric vehicle is mainly composed of stator, rotor, casing, connector, rotary transformer and other parts. Therefore, the upstream of the motor for electric vehicle is the assembly and assembly, wherein the assembly is the third level part of the motor for electric vehicle, the assembly is the second level part of the motor for electric vehicle, and the drive motor is the first level part of the motor for electric vehicle.

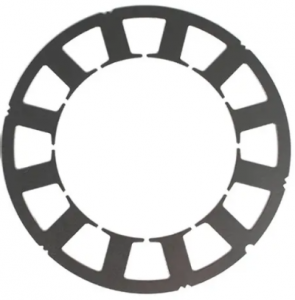

Silicon steel sheet: key component of motor

Silicon steel sheet is the key component of motor and electric appliance. Its performance is not only directly related to the loss of electric energy, but also related to the performance, volume and weight of motor and transformer.

The performance of silicon steel sheet is generally required as follows:

1. Good plate shape and surface coating;

2. High dimensional accuracy and minimal thickness difference of the same plate;

3. It has good electromagnetic properties and grain orientation structure that meets the requirements of application.

Reform of laser cutting technology for silicon steel sheet

- Traditional processing

The traditional processing method of silicon steel sheet is mainly high-speed punching

1.Mold opening is required in the early stage

2.High R & D cost

- Laser cutting

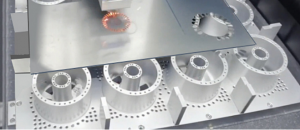

Now, laser cutting is used to form silicon steel sheet, which solves the difficult problem of traditional silicon steel sheet processing.

1. Short R & D cycle, no mold opening

2.Any figure can be cut

3.Flexible and convenient

(Precision alloy instrument laser cutting machine EPLC6045)

EPLC6045 adopts natural granite machine platform, high-precision processing aluminum moving beam and appearance sheet metal packaging, and heat-resistant paint treatment to provide good safety and sealing protection capacity on the premise of meeting the process requirements.

Positioning accuracy: ±3um(X1);±5um(X2);±3um(Y); ±3um(Z);±15arcsec(θ);

Repetitive positioning accuracy: ±1um(X1);±3um(X2);±1um(Y);±1um(Z);±3arcsec(θ);

Plane processing range: 450mm * 600mm, covering the size requirements of most new energy motors (larger format can be customized).

Customized chemical equipment: vacuum adsorption is adopted, and the adsorption area is customized according to the product profile. A variety of vacuum pumps can be selected.

Post time: Aug-18-2022