Fixture System for Laser Brazing

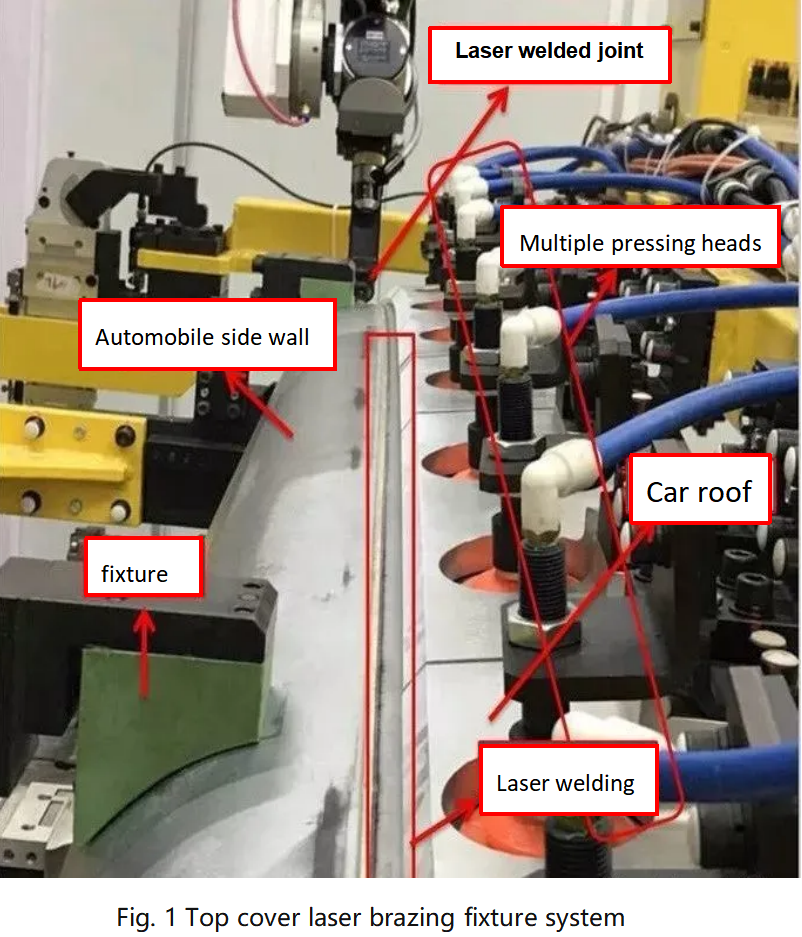

During laser welding, it is necessary to clamp the welded steel plate firmly enough, so special clamps will be designed. The laser welding fixture has a huge volume and complex structure. It is a frame structure as a whole. The left and right sides of the vehicle body are supported by fixture blocks and clamped by cylinders after positioning and support. The upper part is designed with a special positioning and pressing gripper for laser brazing of the car roof, which is pressed with multiple pressing heads. The robot grabs the roof, places it on the body, and clamps it with a cylinder, so that the edges of the body steel plate to be welded fit tightly enough. As shown in Figure 1.

Process factors

• · Temperature

• · Angle of incidence of the laser beam

• · Aggregation and defocus

• · Penetration depth of welding

• · Effect of welding speed on laser welding strength

Test

• 、Visual inspection

• · According to the German standard PV 6917 (can be obtained by contacting the author);

• · Visual inspection shall be carried out for each off-line sub assembly;

• · Focus on the detection of weld penetration (such as incomplete penetration, over penetration and burn through), and take into account the surface condition of the weld (such as spatter and porosity);

The evaluation method of laser brazing visual inspection is shown in Table 1.

|

Table 1 Appearance Quality Evaluation of Laser Brazing |

||

|

Serial No |

Defect description |

Defect evaluation |

|

1 |

Exposed pores |

If conditions permit, the surface can be repaired as long as it does not affect the function; Air holes with diameter greater than 0.2mm must be repaired |

|

2 |

Solder overflow (too much) |

If conditions permit, the surface can be repaired as long as it does not affect the function; Can be repaired |

|

3 |

Layer ripple on weld surface |

The joint must be filled with solder continuously; Can be repaired |

|

4 |

Surface cracks (transverse and longitudinal) occur at the weld |

If conditions permit, the surface can be repaired as long as it does not affect the function; Can be repaired |

|

5 |

Surface cracks (transverse and longitudinal) occur at the base metal |

Unqualified, requiring repair |

|

6 |

Base metal penetration |

Unqualified, requiring repair |

|

7 |

Undercut and incomplete penetration |

Unqualified, requiring repair |

|

8 |

spatter |

If conditions permit, the surface can be repaired as long as it does not affect the function; Can be repaired |

|

9 |

Meatless |

Not allowed, repair required |

|

10 |

The starting end is not welded, and the terminal is pitted |

Not allowed, repair required |

|

11 |

Weld missing (large matching gap) |

Not allowed, repair required |

2 、Destructive inspection

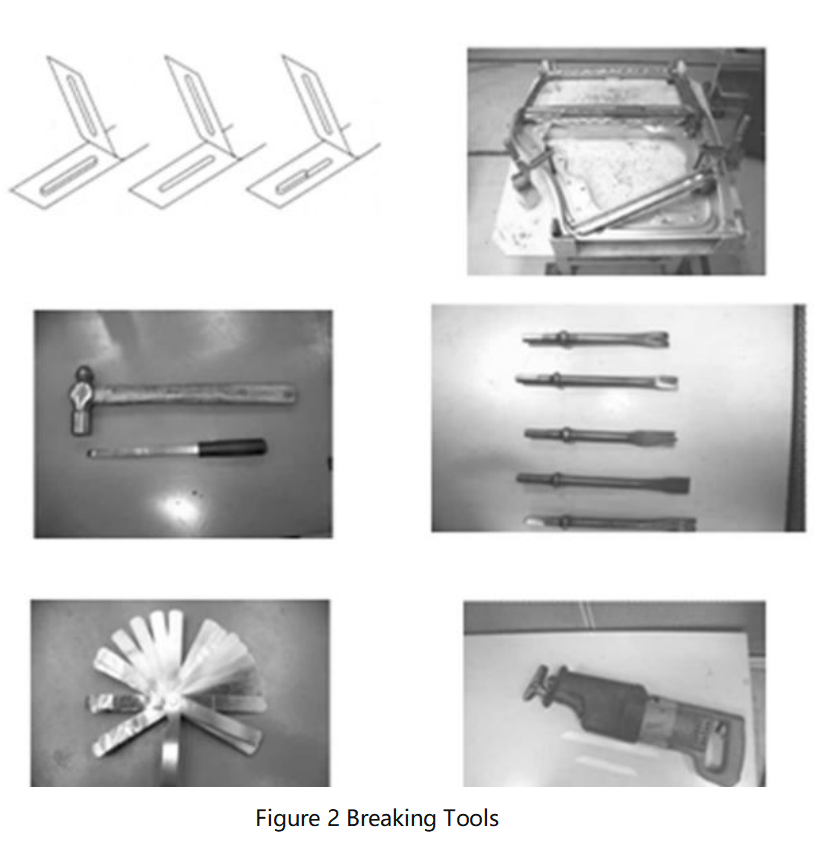

The destructive inspection tools are shown in Figure 2:

3 、Metallographic Microscopic Analysis

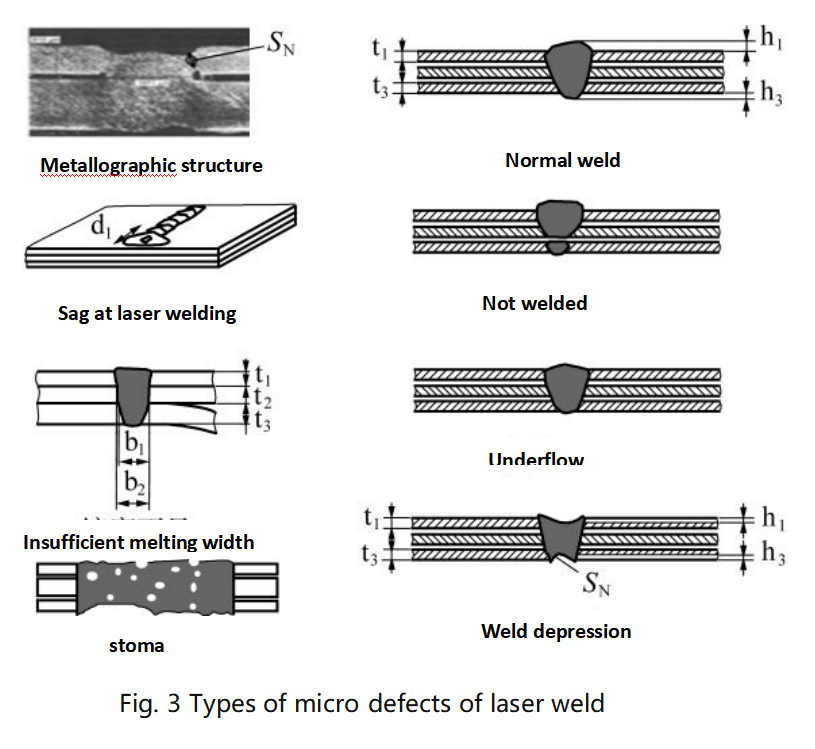

The types of micro defects of laser weld are shown in Figure 3:

4 、NDT

Ultrasonic, X-ray and other instruments can be used to inspect the laser welding quality.

Summary

According to the actual application effect of laser welding technology in automobile plants, it can be seen that laser welding can not only reduce the weight of the vehicle body, improve the assembly accuracy of the vehicle body, but also greatly enhance the strength of the vehicle body, providing users with better security while enjoying comfort. It is believed that with the continuous breakthrough of laser welding technology problems and the continuous improvement of manufacturing process, laser welding will become an important part of the future car body in white manufacturing process.

Post time: Jan-09-2023