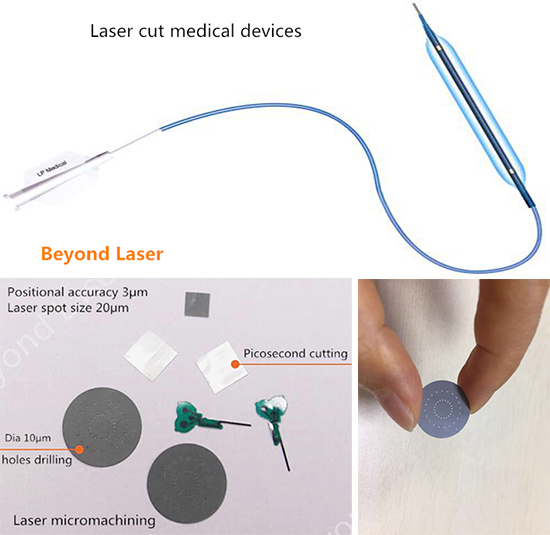

Laser cutting technology is very suitable for cutting blade, precision shaft, stent, sleeve, and subcutaneous injection needle. Laser cutting generally uses nanosecond, picosecond or femtosecond pulse laser to directly ablate the material surface without any post-treatment process, and its heat affected zone is the smallest. The technology can realize the cutting of 10 micron feature size and notch width.

Laser cutting machine is also used in needle, catheter, implantable device and micro instrument for surface texture processing and drilling. Ultrashort pulse (USP) lasers are commonly used. Because the short pulse duration can remove the material more effectively, that is, with less energy output, clean cutting effect can be obtained, and almost no post-processing is required. Laser cutting machine in the micro machining process is not particularly fast, but it is an extremely accurate process. A typical application, using femtosecond ultrashort pulse laser to process the surface texture of polymer tube, can achieve accurate texture depth and height processing control.

In addition, the laser cutting machine system can be programmed to process round, square or oval holes to help control drug delivery through the needle. Different types of micro structures can also be fabricated on different materials, including metals, polymers, ceramics and glass.

Post time: Jul-23-2021